Pally Module

Powered by Rocketfarm

The industry-leading Palletizing Software for Doosan Robotics.

By using Pally software, we could pick the best palletizing components on the market and know everything would sync perfectly. As we scale sales, Pally and MyRobot.cloud make commissioning faster, freeing up our sales team to focus on what really matters—the customer.

See Pally Doosan in action

What Pally Will Do for You

Increased Efficiency

Pally streamlines your operations with intelligent algorithms that optimize palletizing patterns, a user-friendly setup wizard for quick installation, and an intuitive interface that reduces training costs—maximizing productivity while minimizing effort.

Built-In Flexibility & Scalability

Pally adapts seamlessly to different product sizes and pallet configurations, supports effortless pattern changes without downtime, and scales easily with your operations—whether adding robots or upgrading software. Integrating custom hardware into your palletizing solution is no problem.

Serious Savings, Short ROI

Pally offers competitive pricing and tailored hardware options to fit your needs while protecting your margins. Its efficiency ensures a rapid return on investment—typically within a year—so you can focus on growing your business.

Intuitive User Experience

The Pally Operator Panel offers an easy-to-use interface for managing operations post-installation. Users can effortlessly upload, select, and switch between patterns without downtime. Our “partial pallet” feature allows for precise control, enabling users to start palletizing from a specific box number in the pallet – making it seamless. Minimal training is required to make Pally accessible!

Minimized Downtime & Maintenance

With Pally and MyRobot.cloud, you will receive patterns directly from cloud-created palletizing patterns. Receive complete installation files from the cloud for faster deployment and to ensure everything runs smoothly before going live. Complete your Factory Acceptance Test (FAT) without disrupting production.

Enhanced Product Offering

Enjoy total control over your hardware choices. This flexibility allows you to customize solutions, enhance their quality, and put your unique stamp on every project. Smart features, such as fine-tuning path planning and multi-pick capabilities, handle the heavy lifting. This not only reduces wear on your equipment but also increases overall throughput.

What Pally Will Do for Your Customers

Flexible to future changes

• Digital verification is done upfront, and changes are easy to implement.

• There is no downtime in production.

• It is easy to add new products and patterns.

Widen the scope of solvability

• Pally’s ability to multi-grip and utilize the full potential.

• Significant increase in reach from software planning.

Complexity is taken care off

• World-leading software with graphical programming (no code).

• Optimized path planning to increase safety and longevity.

• Access to palletizing experts.

• Possibility to choose their preferred hardware.

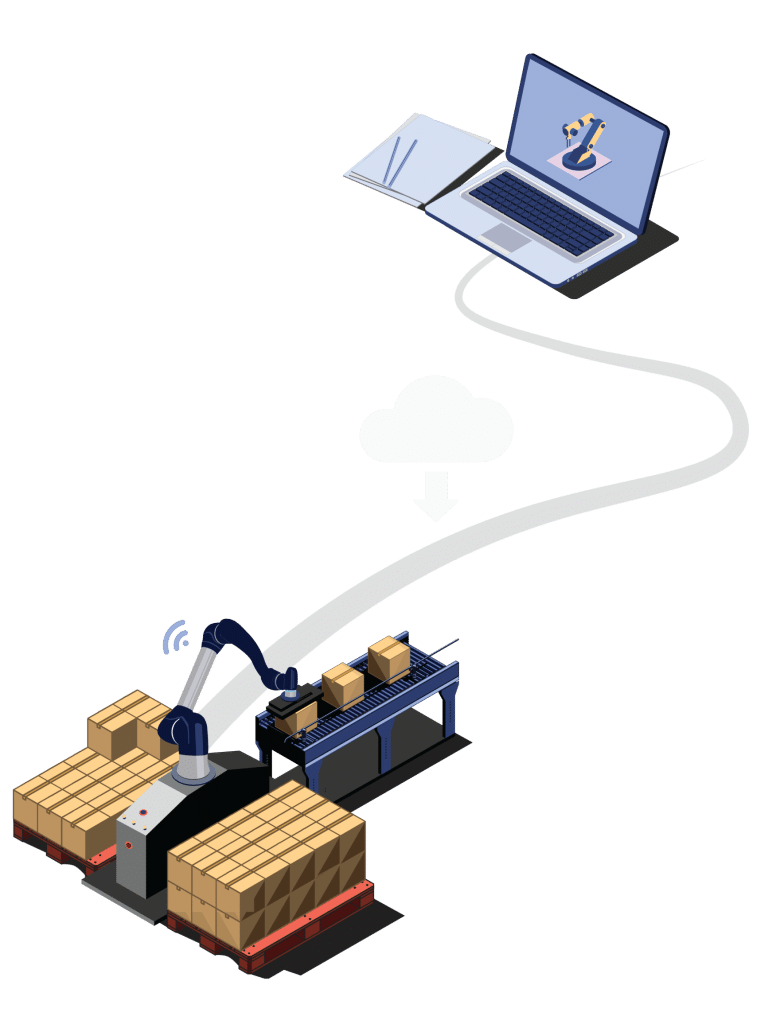

The Ultimate Duo

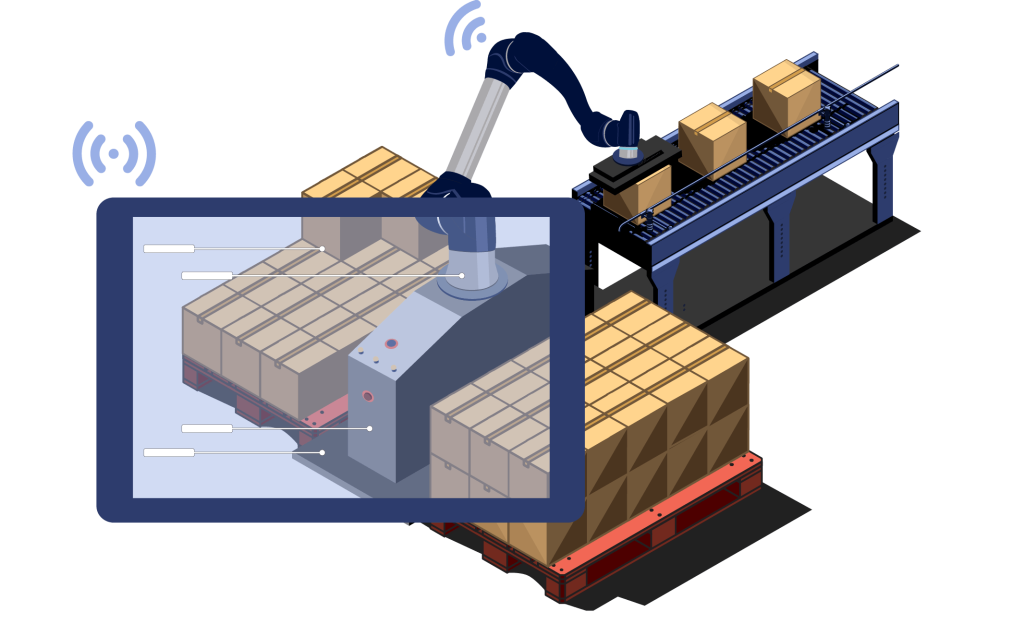

The powerful Palletizing Management Platform MyRobot.cloud takes Pally Module to the next level.

This is why: Design your palletizing patterns, make Pally programs, and choose your robot on the platform. Download the optimized waypoint flow directly to your robot with just a click. There is no need for manual adjustments—just seamless, time-saving automation.

MyRobot.cloud simplifies your entire palletizing workflow. In short:

✅ Save time: Every waypoint is pre-generated and optimized.

✅ Work smarter: Mistakes are eliminated, and performance is fine-tuned.

✅ Stress-free setup: Focus on the big picture while MyRobot.cloud handles the details.

Discover the Technical Features

Learn more about all these features by exploring our Pally Knowledge Base.

Not Entirely Sure What You Need?

Our resource center has interesting articles on palletizing, and our knowledge base has more technical answers.

Want to Speak with Us Directly?

Contact us to discuss partnership opportunities, pricing structures, and how Pally can give your business a competitive edge.

Brigt

Sales Lead

+47 969 14 006 (08:00 – 16:00 CET)

brigt.roysum@rocketfarm.no