Pally

Powered by Rocketfarm

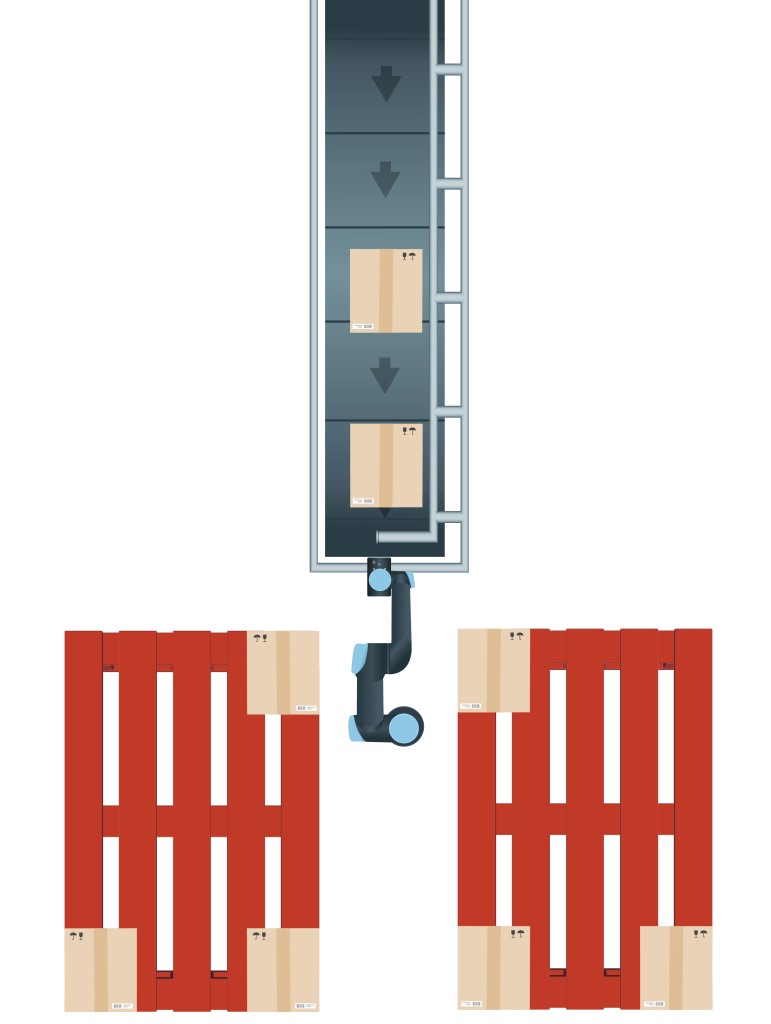

The Leading Palletizing

Software for Universal Robots

Pally is the brain behind our cobot palletizing solution miniPAL®.

The software allows miniPAL® to do more and to benefit more customers. We build the hardware, and Rocketfarm builds the software, allowing us to create the best possible solution.

What Pally Will Do for You

Intuitive User Experience

The Pally Operator Panel offers an easy-to-use interface for managing operations post-installation. Users can effortlessly upload, select, and switch between patterns without downtime. Our “partial pallet” feature allows for precise control, enabling users to pause and resume the palletizing process seamlessly. Minimal training is required to make Pally accessible to all.

Seamless Integration

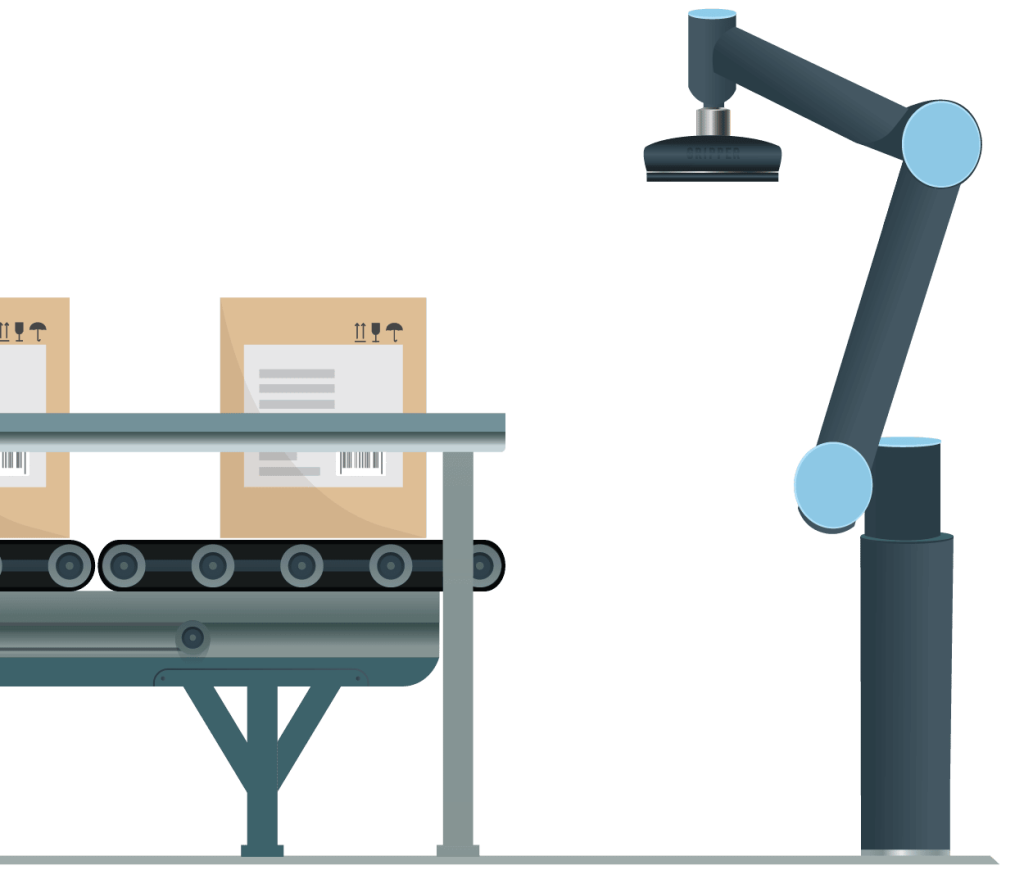

Pally makes integrating new solutions easy. Our Calibration Wizard ensures a smooth hardware and software setup, allowing you to quickly integrate with any gripper or lifting column, custom-built or off-the-shelf.

Minimized Downtime & Maintenance

With Pally and MyRobot.cloud, you can test patterns online, ensuring everything runs smoothly before going live. You can also verify patterns and complete your Factory Acceptance Test (FAT) without disrupting production.

Enhanced Product Offering

Enjoy total control over your hardware choices. This flexibility allows you to customize solutions, enhance their quality, and put your unique stamp on every project. Smart features like optimized path planning and smart grip do the heavy lifting, reducing wear on your equipment while increasing the throughput.

What Pally Will Do for Your Customers

Flexible to future changes

• Digital verification is done upfront, and changes are easy to implement.

• No downtime in production.

• Easy to add new products and patterns.

Widen the scope of solvability

• Pally’s ability to multi-grip and utilize the full potential.

• Significant increase in reach from software planning.

Complexity is taken care off

• World-leading software with graphical programming (no code).

• Optimized path planning to increase safety and longevity.

• Access to palletizing experts.

• Possibility to choose their preferred frame, lifting column, and EOAT.

Verify Your Customer’s Palletizing Project

- Spend 5-10 minutes in MyRobot.cloud – Fast Track to Robot Palletizing

- Simulate the project in the cloud (complete within 1 hour)

- Receive a detailed project report and visualizations

- Share results with colleagues and decision-makers

Optimized for Universal Robots Compatibility

What Can a Pally UR Robot Palletizer Handle?

Discover how Pally’s advanced palletizing solutions can meet your customer’s needs!

Pally can efficiently handle your palletizing demands if the products and CPM requirements fall within our optimized performance ranges.

Discover the Technical Features

Learn more about all these features by downloading the user manual or exploring the Pally Knowledge Base.

Become a Leading Palletizing Solution Provider

Offer the market-leading palletizing solution your customers are looking for, and with our support, position yourself as a top palletizing solution provider.

Are you curious about the companies we work with? Our global partner network includes solution providers, distributors, and automation specialists in over 20 countries worldwide. Learn more about them and their Pally-powered solutions.

Not Entirely Sure What You Need?

Our resource center has interesting articles on palletizing, and our knowledge base has more technical answers.

Want to Speak with Us Directly?

Contact us to discuss partnership opportunities, pricing structures, and how Pally can give your business a competitive edge.

Brigt

Sales Lead

+47 969 14 006 (08:00 – 16:00 CET)

brigt.roysum@rocketfarm.no