Sometimes we find ourselves struggling to find new ways to improve upon internal manufacturing processes. A good start is to look at what resources are already in place. In many instances, putting money into better equipment, tools and hiring new employees can be a great start for improvement. In other cases, as a part of a long term process, automation is often a good solution to become a more efficient and successful company.

But there are a few common misconceptions about investing in automation, which we believe stops a lot of companies from looking into automation. Automation with robots is not only for bigger companies with a large pool of investment money. Automation can be for everyone, if done right. There is a huge potential for small and medium-sized enterprises (SME’s) to start small with automation.

This article will address a couple of old assumptions that are commonly associated with investing in automation. Afterwards, we will present how you can start small with cobot automation solutions. The road to automation is closer than you might think!

Misconceptions

Automation starts with a large investment

It is often assumed that automation is a massive investment only suitable for big manufacturing companies. Luckily, there have been major advancements in technology and software, making cobot automation widely more accessible and easier to operate. The result is a number of different and cheaper solutions to match the needs of companies in all sizes. Therefore, this assumption is out of date.

What is a collaborative Robot? Get a full introduction to cobots here

Automation is a one time investment

An investment in automation should not be seen as a one time thing. Automation should be looked at as a continuous journey of improvement in the business processes. This will help your business tune into the mindset and the realization that investing automation is a realistic option.

Starting small with automation, potentially with a cobot, can be one of the most influential impacts in terms of future opportunities for both scalability and adaptability – eventually contributing to becoming a successful business.

Click here to learn more about the benefits with automated palletizing

You have to be an engineer to operate a cobot

It takes knowledge to install and ensure a stable cobot solution with quality results. This knowledge can be hired externally or you can invest in your staff to acquire the knowledge needed for installing and setting up a cobot.

But after installation, you don’t need to be an engineer to operate a cobot. Cobots are designed to work alongside human workers and will in most cases have a very intuitive and user friendly operating interface.

See below for good tips on how to acquire the knowledge needed to find the right solution for you.

How to get started with cobot automation

Find the possibilities in your production facility

Map out your processes and start to locate the low-hanging fruits for automation. You shouldn’t expect to find every single possibility, but if you have a production line with a lot of manual processes. There will surely be several processes where automation should be fairly simple to implement.

If you don’t know where to start, then talk to an expert (see below)

Talk to the experts

All cobot manufacturers are eager to sell robots. Reach out to a company, for example Universal Robots, and ask them for guidance.

Reach out to your local business network to hear about other companies experience with automation and cobots. Go for a company visit to learn from others who have started the journey. Get inspired, learn from their mistakes and their wins.

Educate yourself

Use the resources available and educate yourself on automation. There’s a plethora of article, webinars, podcasts and online training courses (a good example is the UR Academy). Nevertheless, it is wise to create a basic understanding of automation before you get started. And keep educating yourself for the best possible result.

Include the entire organization

By including the entire organization in the goals, the means and the possibilities when starting the automation process, you are much more likely to succeed and make the cobots are key part of your business.

And maybe someone in your staff already have experience with cobots and automation. Including your entire organization is also a great way of unleashing the human potential among your employees.

TaylorMade associates remain excited and enthused to work side by side with our new Robo Temp that has taken the heavy repetitive lifting motions out of their standard work tasks.

Kenny Rhinehart

Director of Operations at the TaylorMade Golf Ball plant in South Carolina

Everyone can automate

No matter size and resources, automation is possible, it’s just about finding the right way to start using automation.

An important aspect of bringing automation solutions to smaller companies is that it has to be reliable, efficient while also easy to operate. This way, these companies avoid most of the additional costs in the installation phase, maintenance, training and even help avoiding potentially serious injuries in the workplace.

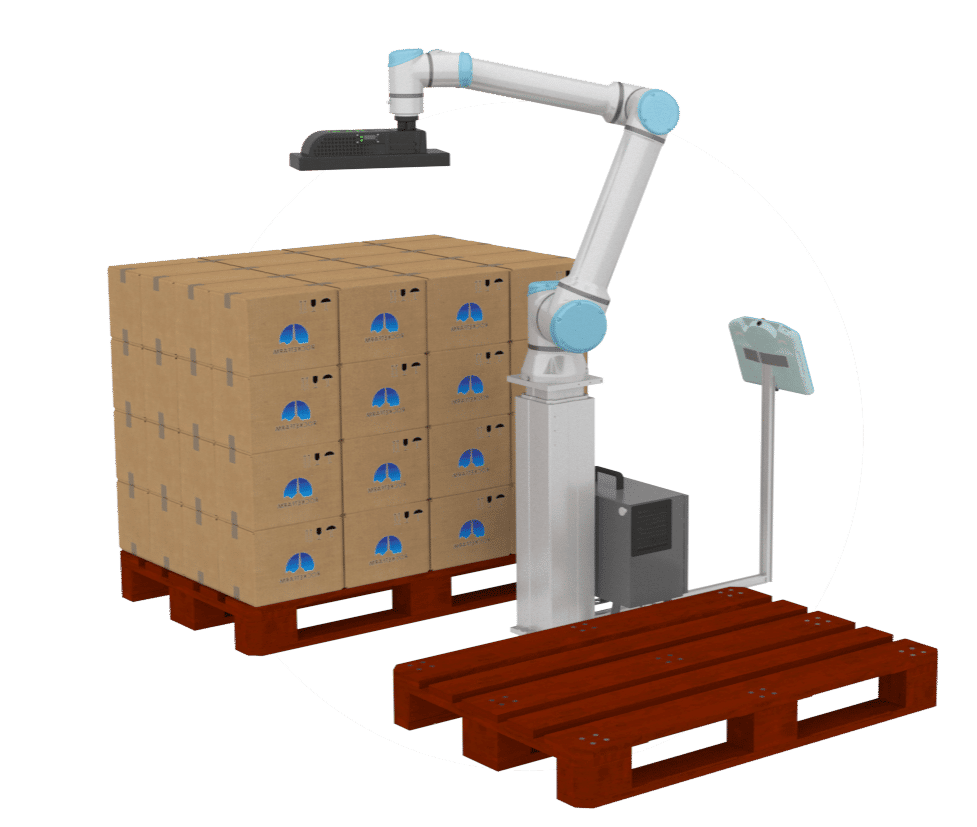

Example: Start with cobot palletizing

One example of automation is cobot palletizing. An end of the production line solution which is helping many small production companies placing finished products on pallets. A palletizing solution can contribute to optimizing the manufacturing process, allowing future improves in production and growth.

Cobot palletizing is a great place to start if you want to start small with automation.

- It’s an end-of-line task that is often separated from other tasks on the production line

- Palletizing is a boring, repetitive and potentially harmful task for your employees.

- Due to the above – it’s a perfect task for a cobot

How to begin the journey?

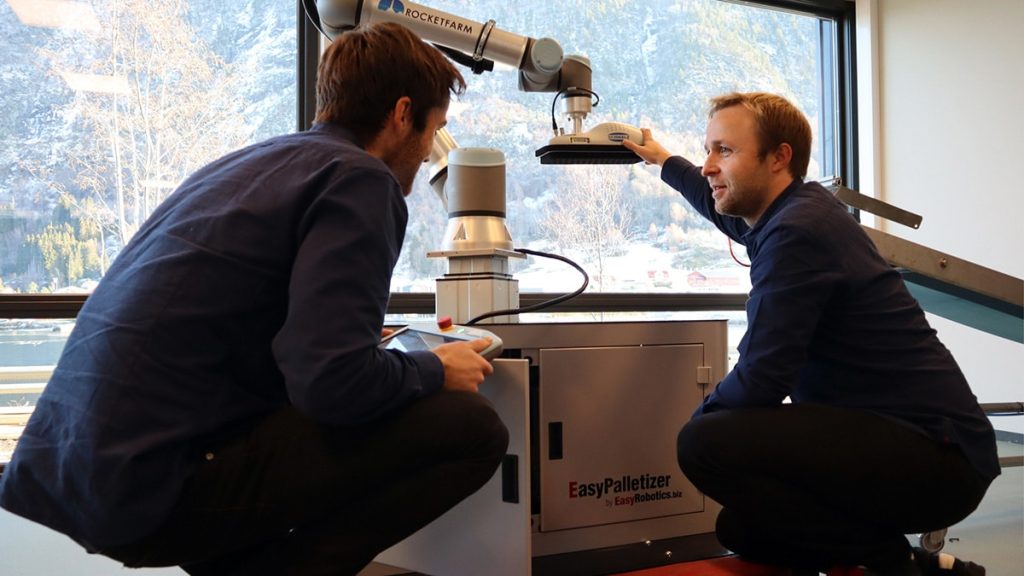

First, you need to make sure that your product can be palletized using cobots. There are some requirements that need to be fulfilled in order to proceed further into the process. Rocketfarms Pally Palletizing solution comes with cobots from Universal Robots, the leading manufacturer of cobots. We will use this solution to showcase how to get started.

UR cobots are well designed for palletizing and can handle products that are weighing under 15 kg and have a production rate less than 30 cases per minute.

If your products are below 15 kg and you have a production speed of less than 30 products per minute. A UR cobot palletizing solution can potentially automate your palletizing.

A complete look into palletizing with Universal Robots

Design and discover available solutions online

If your products meet the requirements, you can start building your pallet in our cobot palletizing search engine tool. This is the Fast Track to Cobot Palletizing. Here you can enter the dimensions, the weight of your products as well as the speed of your production. The engine will then create and deliver you a digital twin simulation and a project report within one hour.

This will serve as an upfront verification, meaning that the solution is digitally tested and verified that it will work once installed at your facility. Additionally it will also suggest available solutions based on your region and product specifications.

Final step towards palletizing automation

As mentioned earlier, we recommend getting help from a certified integrator to get started with cobot automation. After a successful upfront verification we can put you in contact with one of our approved Pally partners (all approved UR distributors of UR system integrators) in your local area. They will be able to help you with SAT, FAT and training of your staff.

It doesn’t have to be complicated

It is actually that easy to get started with automation. It will require some of your time and it will require an investment in hardware and training. But it doesn’t be an all or nothing investment. Cobot palletizing is great example of starting small with automation and the complete costs of a Pally Palletizing solution starts from 70.000€ (varies from area to area and from integrator and the specifications of your project).

Key takeaways from starting small with automation

To recap key takeaways from this article, we have talked about how starting with cobot automation does not need to be a massive investment and how misconceptions are keeping SME’s from starting with automation.

We have talked about how to get started with automation and especially focused on the fact that automation should be a part of a continuous journey of improvement and not a one-time investment.

To showcase how simple it can be to get started with automation we used cobot palletizing as an example. Here we examined how you can use digital twin simulation for early upfront verification of your project and how the process towards getting an installation at your facility could look.

Through this article we hope that we have helped you towards starting small with cobot automation. If you have any questions regarding automated palletizing with cobots please do not hesitate to reach out to us.

Reach out if you would like to learn more about how Pally can help you achieve your goals in automated palletizing.

Brigt Grepstad Røysum

Sales Lead at Rocketfarm AS

Sign up for our newsletter and get a FREE ebook

By signing up for our monthly newsletter, you’ll get case stories, product launches, and tips to automate your production line!

Additionally, you will instantly receive an ebook about implementing palletizing. For more information, please visit our newsletter subscription page.