Oftentimes operators and the production employees on the ground are sceptical to introducing a robot to the production facility. There’s a lot of uncertainty and rumours about robots, but our experience is that employees are hugely satisfied with the robot after installation. When they see that the robot is not there to replace them, but to improve the working environment and relive people from doing robotic jobs.

I don’t think it’s weird, that the employees in packaging are absolutely thrilled that the UR cobots have taken over the monotonous and heavy palletizing work. They also praise the cobots for being flexible, easy to manage and in general there’s very little trouble with the cobots.

Read the full story of our the Cobot palletizing solutions at Maskinpakking, a leading co-packinging company in scandinavia.

Avoid the initial scepticsm

We want to improve work environment

It’s a Rocketfarm core value that we want to improve the working environment at our customers production. People shouldn’t do a robots job. And palletizing is certainly a robot job. It’s not as simple as most people think to automate, but once Pally is installed the movements are the same over and over again. It’s heavy, it’s dull and potentially dangerous to the health of the employees. In other words it’s the perfect job for a robot.

In our business all of the employees took part in the palletizing from time to time, but it wasn’t a popular task. They hated it, to be honest.

Evan Lewis

CEO at Aegir Brewery

We’re talking very big volumes. For some products an order is 600 pallets. With manual palletizing our employees could have workdays where they moved 7 tons.

Knut Thomassen

Maskinpakking AS

Empower your operators

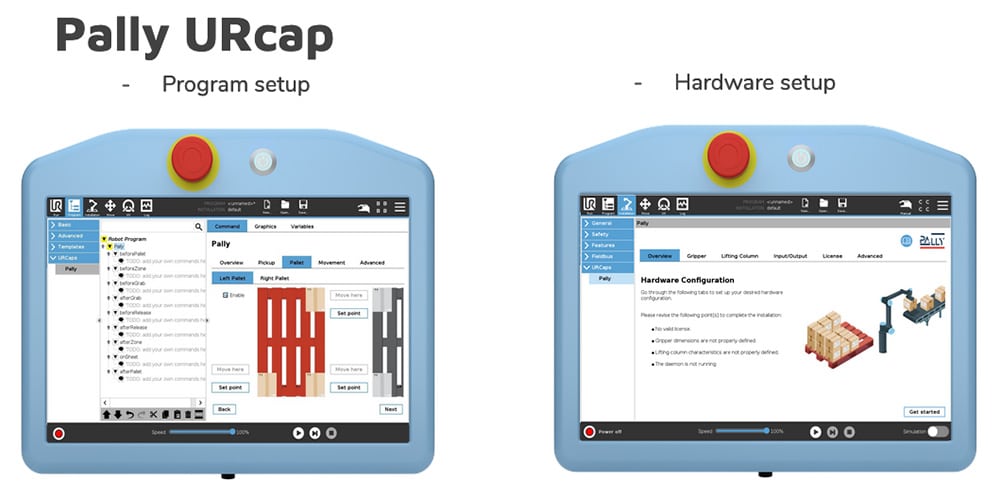

By automating your palletizing process you can empower your operators and have them do more human work, by using their skills to operate the robot and ensure that it is always running and palletizing the way it should. With a Pally Palletizing solution you can get access to Pally Operator Panel (POP), which is a user-friendly operator panel.

POP lets your employees opreate the robot through a simple and easy-to-use interface. It also presents useful data about the palletizing process in real time. You can also use the POP to confirm Left or Right pallet for palletizing. This might sound simple, but no other palletizing solution offers an operator panel like this. And the POP is available in 11 different languages, to make is easy-to-use and accessible for every operator.

Learn more about the Pally Operator Panel

Your operators will be able to use their skills better and do less robotic work and more human work. A cobot palletizer is not here to steal anyones job. It’s here to improve the jobs of your employees.

The people we have in our organization are very experienced, educated, and they bring a lot to the business. So why did I hire a robot? For the same reason I’ve done a lot a choices in the business: I don’t want to wear my people out.

Evan Lewis

CEO at Ægir Brewery

Get Started now

The right time for automation is now. And it’s easy to get started. You can get started in three easy steps and it will take you less than 10 minutes.

- Enter the Fast Track to Cobot Palletizing

- Provide us with some basic information about your product, pattern and region

- Get a simulation and a project report within one hour

A simulation and a project report from Rocketfarm is your upfront verification of your cobot palletizing project. It will even match you with available solutions in your region.

It uses advanced digital twin technology to precisely imitate the performance of a UR Cobot Palletizer for your specific product. This is the easiest, the cheapest and the best way to start your road towards an automated palletizing solution.

Sign up for our newsletter and get a FREE ebook

By signing up for our monthly newsletter, you’ll get case stories, product launches, and tips to automate your production line!

Additionally, you will instantly receive an ebook about implementing palletizing. For more information, please visit our newsletter subscription page.