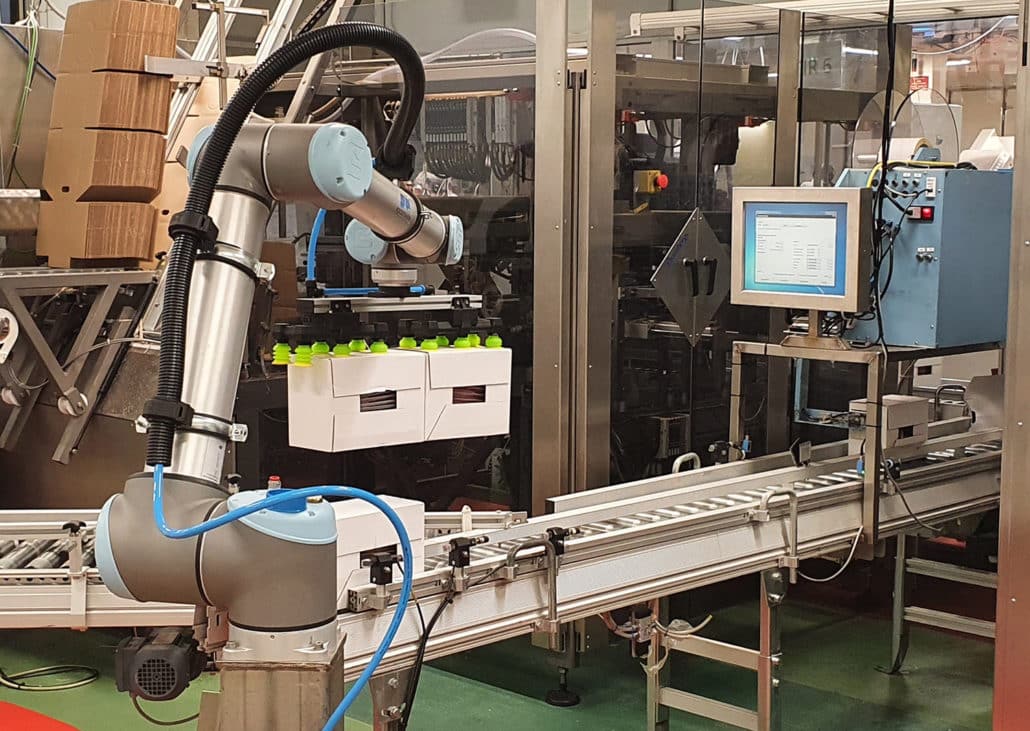

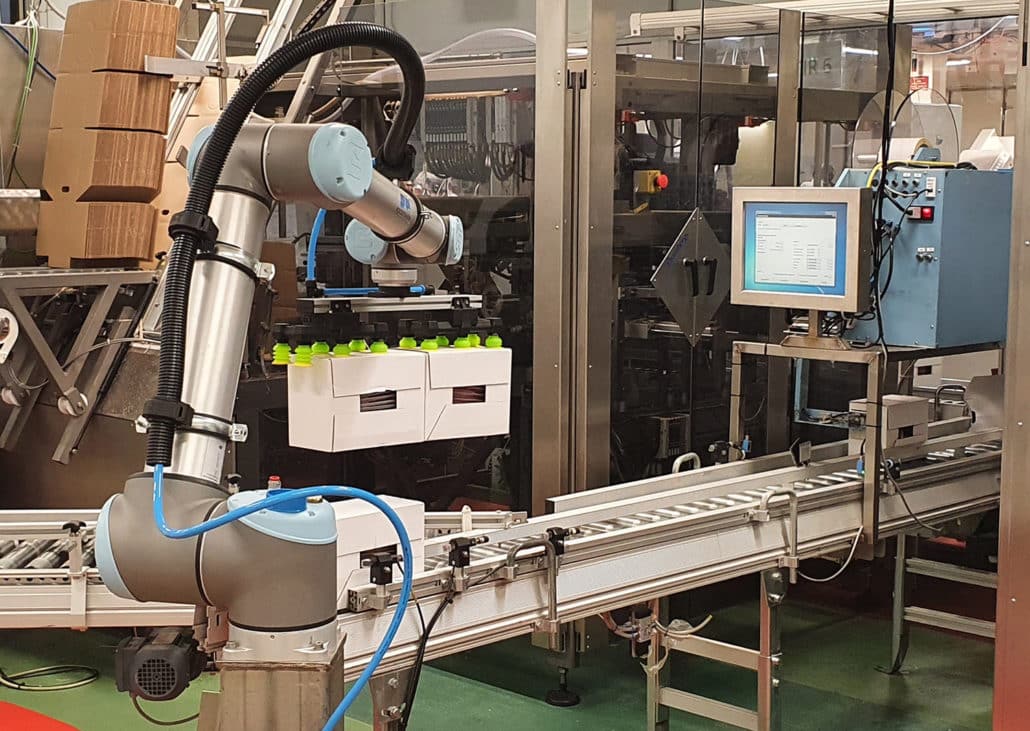

A story about how Pally increased performance 30% on cobot palletizing solutions, which have already been working for 6 years.

Nortura has had 3 collaborative palletizers since 2015. Back then we installed the robots at their factory in Sogndal and developed what was to become the predecessor for Pally.

Fast forward 6 years of impeccable palletizing and Nortura needed to upgrade their customized software to keep the production futureproof.

The implementation of Pally resulted in a major improvement in performance, stability and flexibility.

Our very first palletizing customer

Nortura was Rocketfarms’ very first palletizing customer back in 2015. It was way before we had decided to launch Pally as a product and back when we thought palletizing was a simple robotic task.

We’ve learned a lot since.

We thought palletizing would be a simple task and gave Nortura a really good quote. Once we got into the development, we learned that palletizing is by no standards an easy task. This quote was definitely not very profitable. But it was the foundation for Pally.

Halvor Gregusson

Founder of Rocketfarm and project manager for the first Nortura installation.

We no longer offer system integrations services and instead refer to our many global partners.

Bought two more within 1 year

After just 1 year of use, Nortura were so happy that they decided to purchase two additional collaborative palletizers to further decrease the strenuous work for the staff.

Read the story about the original palletizing installation over Universal Robots

Impeccable palletizing for more than 5 years

After 5-6 years of continuously palletizing the robots needed an upgrade to stay on top of the current production and be ready for a faster production line in the future.

This is despite the fact that:

The cobot palletizers are the robots we have with highest operating time and lowest running costs. We have been very happy about our first installations and are very excited that Rocketfarm could help us improve the robots for us to take the next steps in improving our production line

Says Inghild Lysne Sanden, Factory Manager Nortura Sogndal

Read about just how reliable UR cobot palletizers are

So Nortura SA Sogndal reached out to Rocketfarm to hear if it was possible to update the robots and make them fast enough for the future.

The upgrade

The robots got a software update and installation which also allowed for hardware alterations:

- Upgraded Polyscope version,

- Installed Pally (our palletizing software and the fastest collaborative palletizing software in the market)

- Removed the vision system

- Replaced the grippers

With the help of our Pallet Builder, Nortura could create new patterns with interlocking layers to replace the shim paper routines of the old patterns. This also decreased the running palletizing cost.

Pally has seen major upgrades since our early versions of the software. With Pally 2.7 version installed at Nortura they immediately saw an improvement in several key areas, especially since they were palletizing using custom coding.

- Introducing the Operator Panel

- Improved path planning

- More possibilities for changing patterns

The results of the retrofit

These improvements have led to a 30% higher palletizing output and higher flexibility for Nortura.

Their engineers and operators can now easily operate the robot on their own. The updated software allows Nortura to more easily change the palletizing patterns themselves (via our web-based Pallet Builder) and easily integrate them into the robot. Making it easy to adjust to future changes in production.

We are investigating how to create an increased production output, without making large investments. With this retrofit, we managed to increase the performance and give our collaborative palletizers, which have already many years ago returned their investment, a new and better life for many more years.

Inghild Lysne Sanden

Factory Manager Nortura Sogndal

Only 8 hours of downtime

The retrofit happened with one day set aside for the installation of each robot. We could install the retrofit, with only a downtime of 8 hours in production per robot. Something Nortura highly appreciated, as they had expected up to a full week of downtime to install the robots!

Verify your palletizing project with a 3D Digital Twin Simulation

Proving the increased performance before installation

By utilizing the power of Rocketfarm Simulations we were able to figure out what changes would be beneficial to install and prove to Nortura what increased performance they could expect from retrofitting their cobot palletizers. This allowed Nortura to quickly determine the ROI for the upgrade.

Rocketfarm Simulations inserts a physical solution into the digital world and enables easy changes in settings, hardware etc. allowing us to digitally engineer the best possible physical palletizing solution.

Nortura exported their robot file and sent it to us and we were able to do digital engineering and testing from our laptops and quickly deliver trustworthy results to the managers at Nortura (this is just one of many use cases for Simulations).

Live data now available

Another benefit from the retrofit is the ability to export live palletizing data from Pally, so that the operators at any time can keep an eye on the process and make sure the robots are running smoothly and optimize the production line.

An example of the data that’s available in Pally are CPM on current pallet, CPM on previous pallet and Time remaining on Pallet. The latter is a great advantage to operators as this allows them to know for how long they can focus on other tasks before removing the full pallet.

Even “old” robots can deliver better value!

A UR collaborative palletizer with Pally already has a great performance and an ROI in less than 1 year. But with the UR+ ecosystem where software developers from all over the world contribute, the innovation is massive and 5 years can feel like a lifetime.

It is therefore not always necessary to change robot or update to an industrial robot to increase your production performance. It’s very possible that improved software can solve your problem.

And Nortura, they are still super happy with their 3 palletizers, now 30% more than before. The robots adding value for every day of production

Sign up for our newsletter and get a FREE ebook

By signing up for our monthly newsletter, you’ll get case stories, product launches, and tips to automate your production line!

Additionally, you will instantly receive an ebook about implementing palletizing. For more information, please visit our newsletter subscription page.