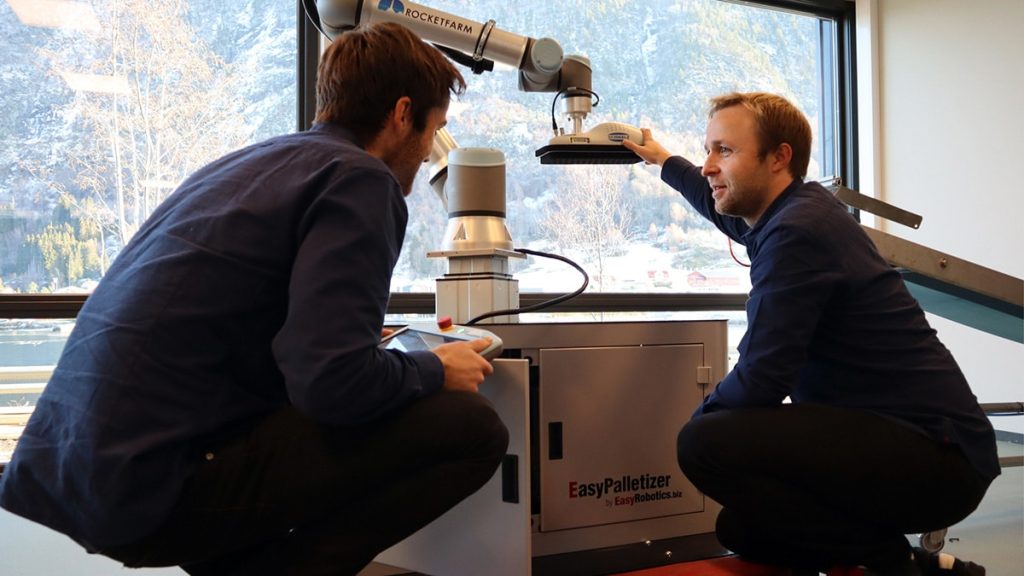

We had one goal in mind when we decided to create a new path for Rocketfarm: to create the best palletizing software for Universal Robots on the market.

After hundreds of hundreds of hours of thinking and writing code, and days, weeks, and

years of planning and discussion,

we could finally proudly present our Pally software.

The Pally journey is divided into three vital parts: The Pally URCap, MyRobot.cloud, and the Pally Operator Panel.

1. The Pally URCap

The first part of Pally is the application for the UR robot, a so-called “URCap” (Universal Robot Cobot application).

Imagine the robot as a smartphone and Pally as an app you can download to run on the robot from the App Store.

Pally is designed with a user-friendly interface that guides you through setting up your palletizing robot with easy steps. It’s similar to how great mobile apps work.

Check out our URCap in the UR+ Ecosystem

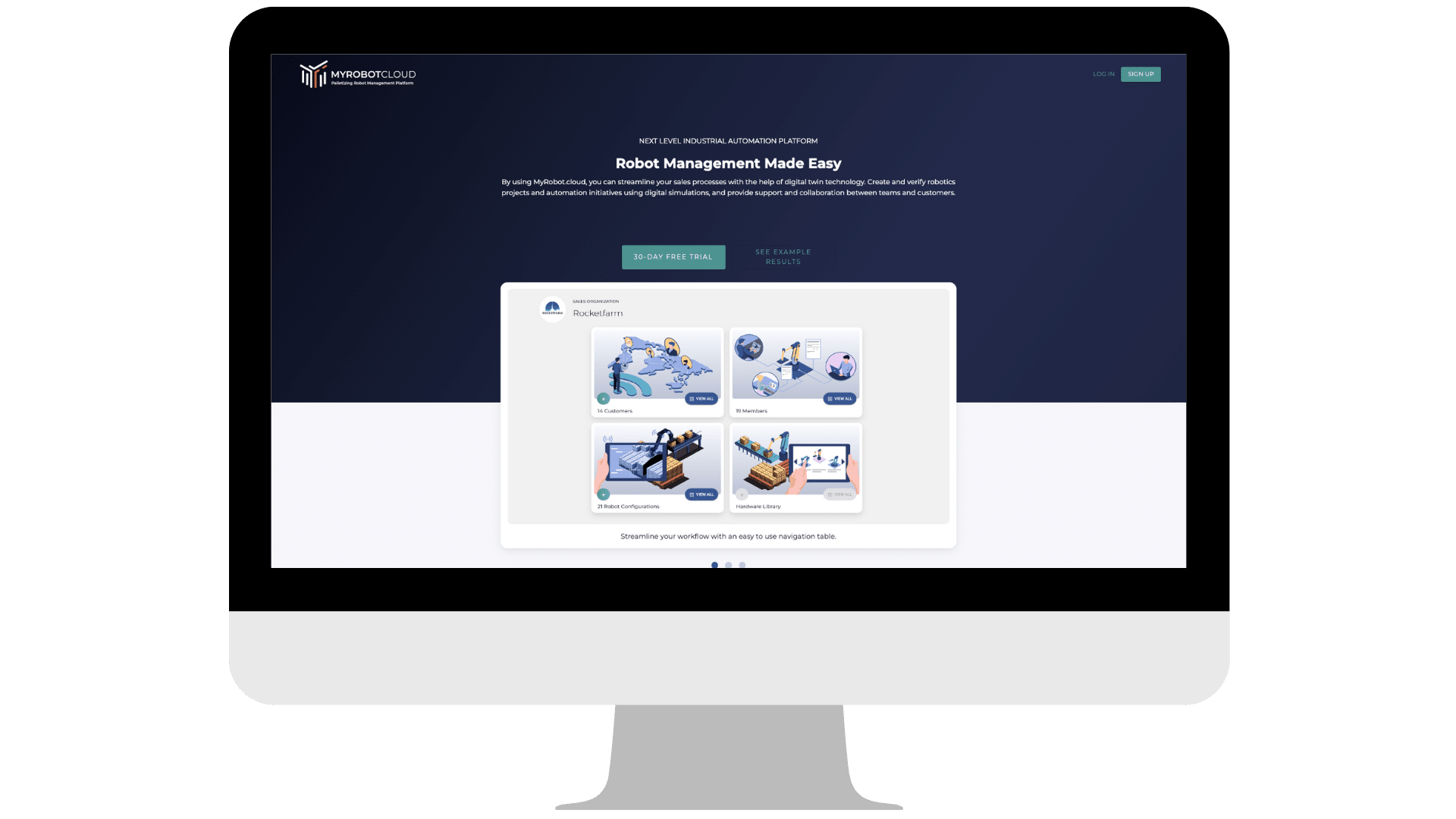

2. MyRobot.cloud

The second step of Pally is MyRobot.cloud – the Palletizing Robot Management Platform. This is our web-based palletizing robot management platform, where you can create your desired pallet layout and run simulations with your digital twin.

The biggest advantage of our simulations is that they run on the exact same software as an actual UR robot does: the latest Polyscope and the latest Pally version, and this is what we consider a digital twin.

The main benefits of digital twin simulations are the possibility to validate projects upfront and optimize patterns and robot configurations, in addition to being an effective sales tool. When it comes to the validation of projects, the simulation tool can function as a virtual FAT.

In addition, it can be applied to patterns and robot configurations to increase the overall performance of the cobot. At the same time, the simulation tool also has great commercial value. By providing trustworthy visualizations of the projects, it will be easier to convince the customers that the solution is the right one for their palletizing project.

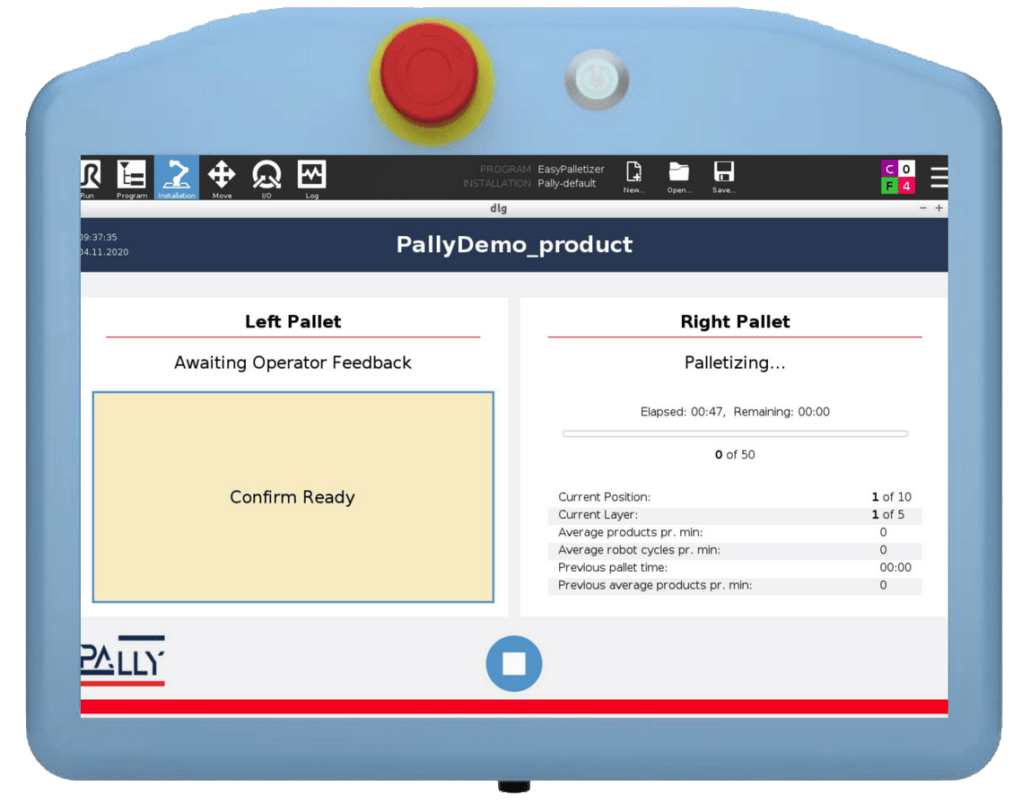

3. The Pally Operator Panel (POP)

Then, when you are all set to start palletizing, something very important usually happens. Several people are going to deal with the robot on a day-to-day basis. These operators will start it up, shut it down, choose which product is to be palletized today, reload it with empty pallets when the old one is full, etc. And if you think you dislike awful user interfaces, believe us, these operators hate it even more.

The third part of Pally is, therefore, the Operator Panel, which will provide the end-user with the very simple user interface they need for using Pally on a daily basis.

These three parts combined make our Pally software

Our goal has been and remains to make your day at work a little bit easier and hassle-free and to save your back from the daily strain of lifting an unspoken number of boxes.

Have you previously considered automating the palletizing task in your facility? Or maybe you just started thinking about it now? Either way, we would love to get in contact with you!

Your palletizing solution might just lie a few clicks away!

Fast Track to Cobot Palletizing

If you don’t own a cobot palletizer yet and simply wonder how it all would work if you bought one, you may want to visit our Fast Track to Cobot Palletizing.

Within one hour after completing an easy 3-step wizard, you will receive a digital twin simulation of your products being palletized by our Pally software. This 3D simulation will verify the feasibility of the available cobot palletizing solution based on your region and product specifications.

Sign up for our newsletter and get a FREE ebook

By signing up for our monthly newsletter, you’ll get case stories, product launches, and tips to automate your production line!

Additionally, you will instantly receive an ebook about implementing palletizing. For more information, please visit our newsletter subscription page.