Are you ready to step up your game as a solution provider?

We understand that the cobot palletizing field can feel complex. Choosing the right palletizer, integrating software – these tasks can seem overwhelming, but they don’t have to be.

Our Pally software offers your customers a powerful, easy-to-use palletizing solution that enhances efficiency and streamlines operations.

Pally is a market leader for a reason: it’s flexible, user-friendly, and designed to help you confidently meet your customers’ needs.

We asked our sales executive, Brigt, to share his top four reasons why Pally should be your go-to choice for palletizing solutions.

1: Seamless integration

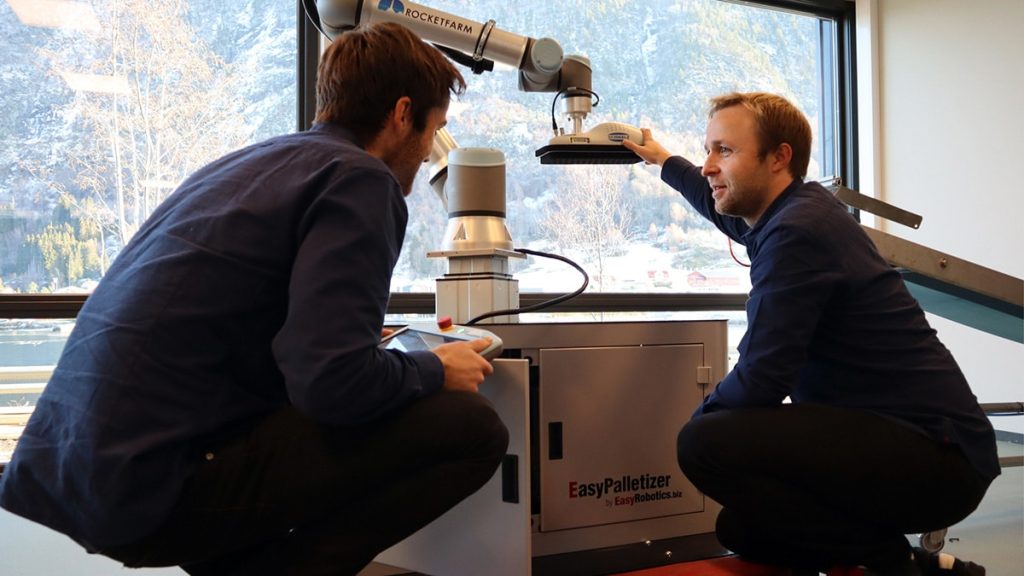

Integrating new solutions can be challenging, leaving end customers with a steep learning curve. But with Pally, the process is straightforward. Cobots have already positively impacted workplace environments across various industries, and integrating Pally with your chosen hardware is just as easy. Thanks to the Calibration Wizard, you’ll smoothly navigate hardware and software calibrations, ensuring a hassle-free setup.

We are also hardware agnostic, so you can use any gripper or lifting column you prefer in your offering. Whether you have custom-built components or choose from our pre-loaded, off-the-shelf options, Pally makes integrating your hardware of choice simple.

2: Minimized downtime and maintenance

Downtime is costly – every minute of paused production means lost revenue. With Pally, this concern is a thing of the past.

Pally and MyRobot.cloud enable you to test patterns online, ensuring everything is a-okay before you go live. Once you’ve verified the pattern and completed the Factory Acceptance Test (FAT), you can download the pattern into your Pally-powered solution without disrupting production.

3: Enhanced product offering

Pally gives you total control over your hardware choices – no dependencies, just freedom. This flexibility allows you to customize your solutions, enhance their quality, and put your unique stamp on every project.

But Pally isn’t just about flexibility; it’s also highly scalable. Once you’ve perfected your standardized solution, you can focus on growing your business rather than constantly developing new systems. And even as you scale, Pally offers customization options so you can adapt and refine your solutions as needed.

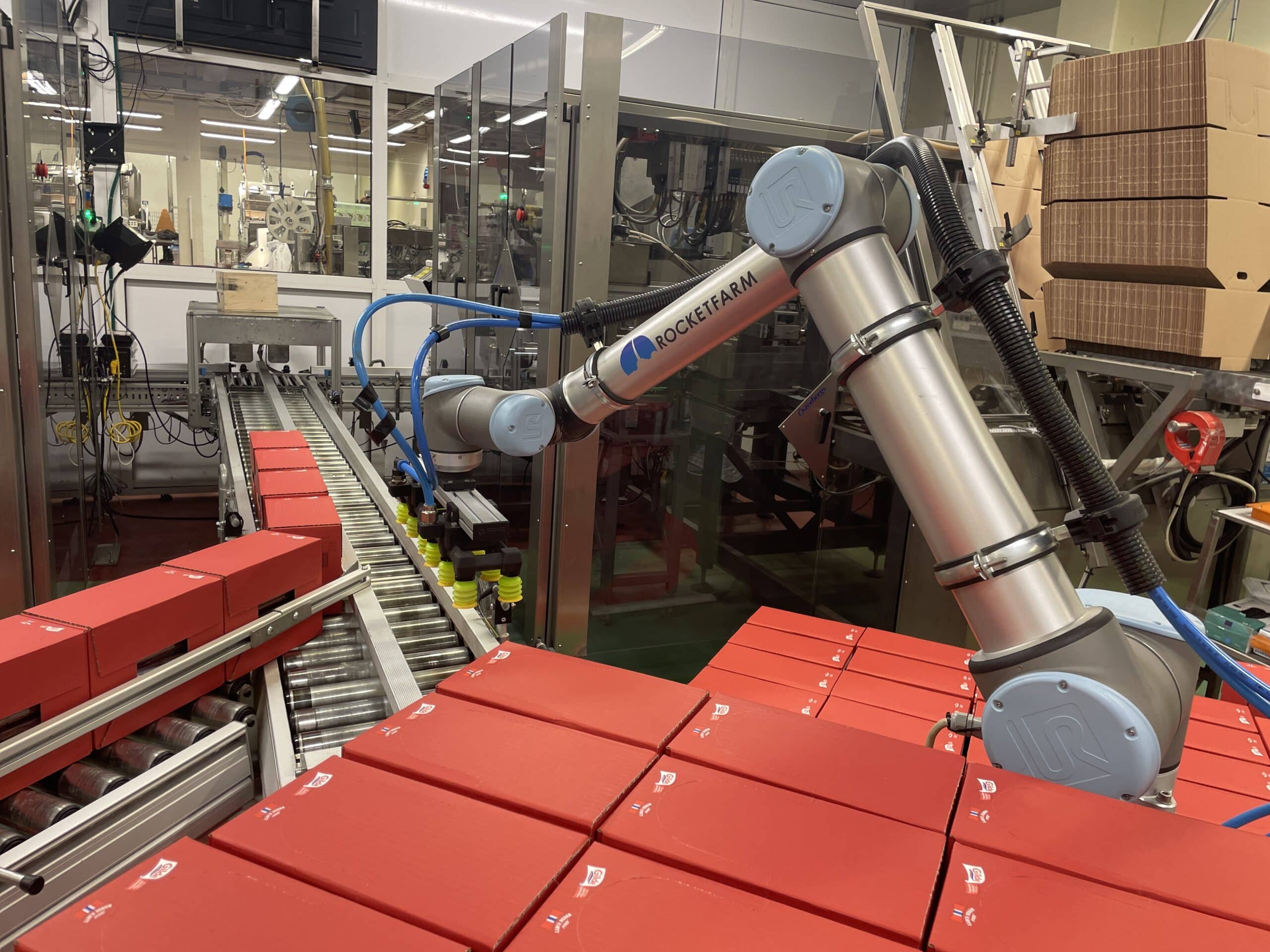

Pally’s smart features, like optimized path planning and smart grip, do the heavy lifting for you.

The software identifies the most efficient path from conveyor to pallet, reducing wear and tear on your robots. This leads to longer-lasting equipment and less maintenance. Plus, smart grip technology increases your throughput, allowing you to handle more boxes per minute, depending on your gripper, pattern, and payload.

In short, Pally empowers you to scale efficiently, customize freely, and maintain high performance—all while reducing strain on your equipment.

Want more technical details? Hop on over to Pally Knowledge base

4: Intuitive user experience

The Pally Operator Panel offers end-users a simple, intuitive interface through which they can easily manage their operations post-installation. Uploading, selecting, and switching between patterns is seamless, with no downtime, and users can effortlessly monitor real-time data. Brigt also highlights the “partial pallet” feature as a significant advantage.

“The partial pallet option allows the end user to adjust start and end conditions, offering even greater control. If anything unexpected happens, you can pause and restart the palletizing process exactly where it left off,” Brigt explains.

Feedback from our customers consistently shows that Pally is easy to use and requires no extensive engineering experience. Brigt notes that only basic training from a distributor or integrator is needed to get started.

Become a leading palletizing solution provider

Offer the market-leading palletizing solution your customers are looking for, and with our support, position yourself as a top palletizing solution provider.

Are you curious about the companies we work with? Our global partner network includes solution providers, distributors, and automation specialists in over 20 countries worldwide.

Learn more about them and their Pally-powered solutions here.

If you want to be part of this network – reach out to us.