Palletizing is critical to logistics and warehousing, especially for small and medium-sized operations and enterprises. Moving boxes from the conveyor to the pallet is labor-intensive and repetitive, often involving many different workers.

Automating this process frees up time for more engaging activities and reduces the overall workload. Moreover, it eliminates one of the most worrying aspects of warehousing operations.

This article will cover how to provide your customers with the optimal palletizing solution so everyone is satisfied.

The role of automation

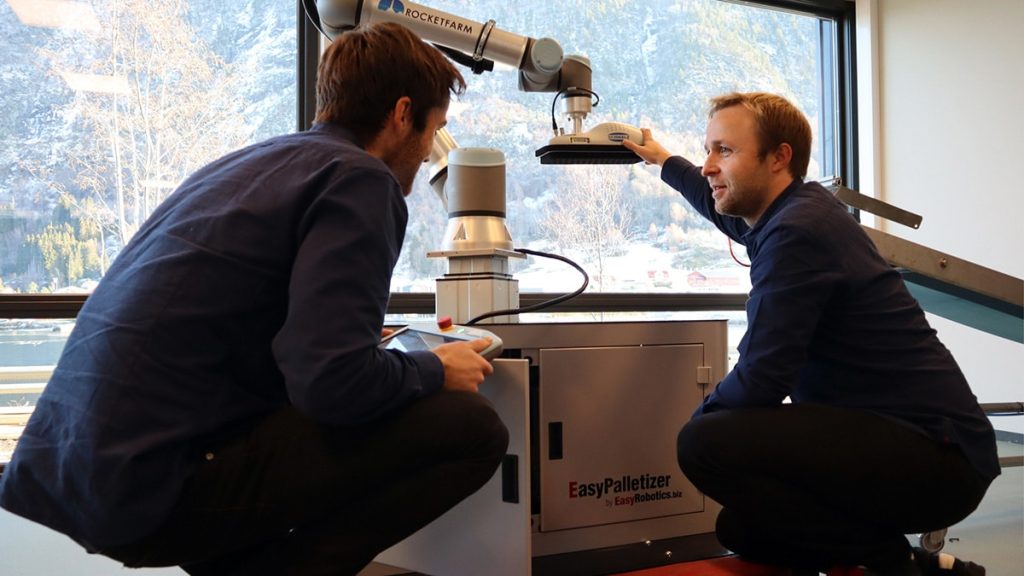

Cobots have made automation more affordable. Historically, automating was a significant investment, but today’s cobots enable small and medium-sized businesses to integrate automation into their facilities. As labor costs rise, customers are more inclined to adopt these solutions.

For larger organizations, cobots might not match the speed of industrial robots, but they offer substantial advantages. Workers can collaborate with cobots, and the absence of fencing saves valuable space. In the face of labor shortages, automating dull and dangerous jobs allows for better utilization of the workforce.

Key Factors to consider when planning a palletizing solution

End customers often begin with the question, “Do I have what I need to implement a palletizer?”

Surprisingly, cobots (collaborative robots) typically require fewer adjustments than anticipated, meaning that significant changes to the facility may not be necessary.

Here are some crucial factors to consider:

- Footprint: Assess the space required for the palletizer and how it will impact current logistics.

- Phased approach: Instead of aiming for 100% automation from the start, consider beginning with cobot palletizing and expanding from there. Ask, “How can I get started?” instead of “How can I get to 100% fastest?“

- Optimal use: Identify the best location in your facility for the palletizer to maximize its benefits.

- Software integration: Using software like Pally can significantly enhance the efficiency of your palletizing process.

- Production needs: Consider any specific features of your production that cannot be changed, such as label direction or barcode scanning.

Want to learn more about the different range of components you should choose from when planning a palletizing solution? Check out this article in our library.

Choosing the right palletizer

Implementing a palletizing solution can dramatically improve a production line.

With software like Pally, it’s possible to palletize up to 60 boxes per minute. While these high numbers are rare, achieving eight cycles per minute with multi-picking is impressive. Other goals include:

- Safety: Letting machines handle heavy lifting to improve worker safety.

- Cost Reduction: A palletizer works consistently, regardless of the day or time.

- Efficiency: Achieving more with less effort.

- Scalability: Ensuring your solution can scale efficiently as production demands increase.

To select the right palletizer, it is essential to have a complete overview of the customer’s requirements.

Consider the footprint, available space, types of products, and whether a single gripper can handle the job. The robot’s size is another crucial factor to consider, regarding the palletizing solutions’ effectiveness.

“Use Rocketfarm’s digital twin simulation to optimize the process for you!”

Lina, Head of Channels Rocketfarm AS

The importance of software

To build the best palletizing solution possible, implementing software like Pally is a game-changer. Why and how, will differ from who is the receiver.

For resellers, Pally offers standardized yet customizable software that can be implemented in just a few hours. This makes handling support and pattern changes easier.

For end customers, Pally optimizes production by ensuring the robot operates safely and efficiently without manual intervention. This user-friendly Pally Operator Panel allows operators to understand and control the solution easily, enabling them to perform other tasks simultaneously.

Palletizing is a major focus area poised for substantial changes in the coming years. While the necessity of software in automation is recognized, its full value is still underappreciated. However, this perspective is likely to evolve as more solutions become available.

Successful palletizing solutions

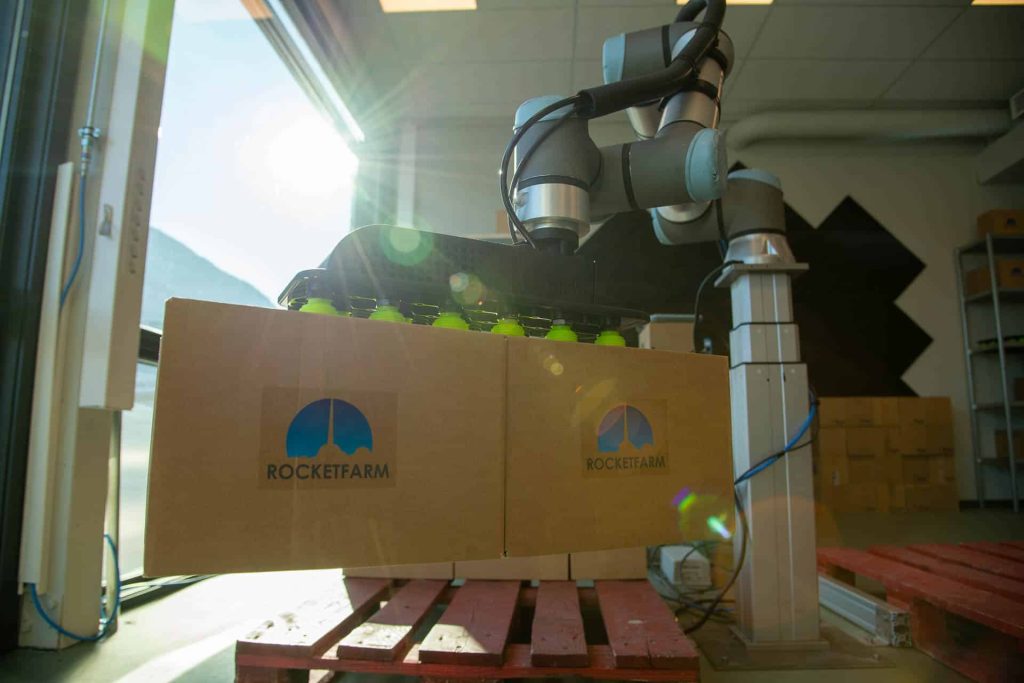

At Rocketfarm, we have extensive experience with cobot solutions. A standout example of a successful palletizing solution is the first Pally installation at Nortura Sogndal in 2015.

“As of 2024, it’s still operational, proving that cobots last well beyond “just a couple of years.” When we say it’s future-proof, we mean it. Pally offers a palletizing solution built for the future.”

Lina, Head of Channels Rocketfarm AS

Our installations showcase the extensive capabilities of cobot palletizing today, and we continue to expand the scope of our robots and software. Cobot palletizing is here to stay!

Get in touch today if you want more insights into palletizing solutions and how they can revolutionize your operations.