Universal Robots has just launched its newest member of the UR cobot family, the UR30. They say only fools do the same thing twice and expect different results. If so, Universal Robots might be fools for releasing the UR30 with the same hardware as the UR20. But I can be a bit foolish sometimes, too!

Either way, the UR30 is another great contribution to UR’s “palletizing class” of cobots from Universal Robots.

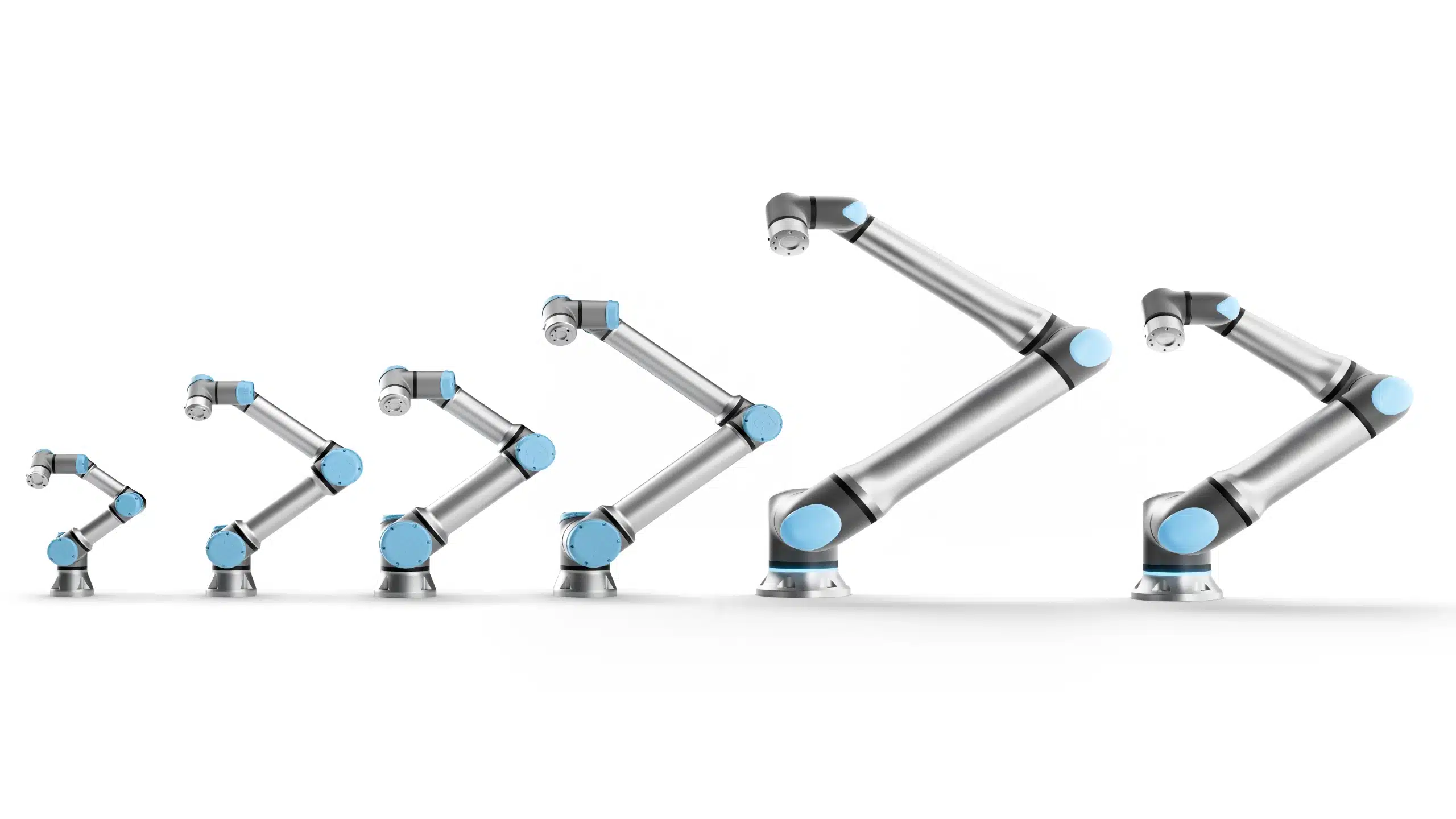

There was a time when the max payload capacity of the UR cobots was 10kg. UR released UR16 using the same HW as the UR10 to increase the payload, shortening the reach to achieve the extra payload.

For palletizing, those extra 6 kgs would make a lot of difference for numerous use cases. But despite being perfectly capable of reaching the far corners of an EU-sized pallet with the right accessories in the palletizing market, it literally fell short.

Now, the same strategy is used again to launch UR30 on the same hardware as UR20, and we applaud it!

Psst! If you have not read it yet, please pause and read this article I wrote on the UR20 when it launched for a more in-depth background.

A market-proven reach

The crucial difference is that the UR30 has a market-proven track record of having sufficient reach for palletizing, thanks to the palletizing workhorse UR10; both reach 1300mm.

With the UR10 already being sold successfully for palletizing, often with a 7th axis lift if the pallets are wide or tall, the UR30 already has the proof it needs to be perceived as a robot with sufficient reach for most use cases. Particularly in Europe, where the EU1-sized pallets are about 200mm slimmer than in the US1.

To be perfectly fair, though, and to geek off, the practical reach of UR30 for palletizing is slightly less than UR10. As the base joint has a wider radius, empty pallets would need to be placed about 80mm further away from the base of the robot to avoid collisions between the base joint and a full pallet, practically reducing the reach by about 100 mm compared to the UR10.

However, our simulations in MyRobot.cloud show, we still have plenty of reach to play with.

The extra 10kg

So, what does 10kg more really mean? Well, you can, of course, lift 27kg of products instead of only 18kg, leaving 10% for accessories like grippers, sensors, and cameras.

More importantly, it enables you to palletize five 5kg products simultaneously with a UR30 compared to three 5kg products on a UR20. In other words: the extra payload is transferred into 60% additional throughput in that scenario, allowing higher production speed. In many cases, this is far more groundbreaking than going from 18–27kg products.

It might not be immediately obvious, but this magical transformation from payload to throughput also exists in the form of payload to safety.

I argue that “bigger is safer” in the previously mentioned article. To avoid repeating myself, I leave that section in the other article.

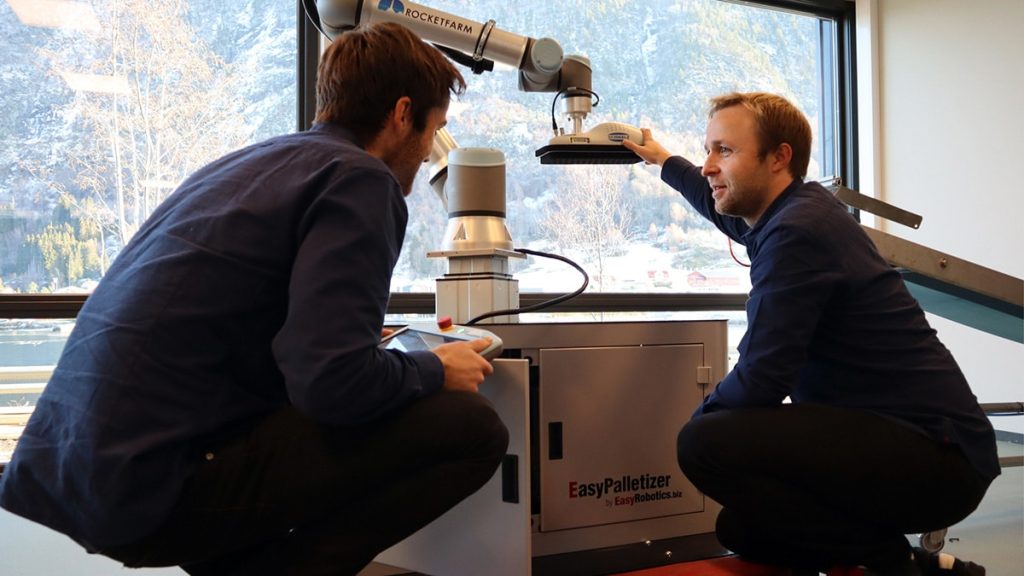

Halvor Gregusson

CIO at Rocketfarm

Can be the friend you need

To keep this article shorter than the UR20 one, I’ll conclude by saying that the UR30 may not be designed for palletizing like its predecessor, the UR20, and may not be the preferred choice for many customers.

However, as a complementary offering that fills gaps in the market that UR20 can not, UR30 can be the friend you need.

If you’re wondering if the UR30 cobot can meet your needs, we have great news! You are now able to experience it for yourself on myrobot.cloud.

Sign up now for a 30-day free trial if you’re eager to put it to the test!

Feel free to reach out if you would like us to analyze your specific project or palletizing needs.

Brigt

Channel Executive at Rocketfarm

Sign up for our newsletter and get a FREE ebook

By signing up for our monthly newsletter, you’ll get case stories, product launches, and tips to automate your production line!

Additionally, you will instantly receive an ebook about implementing palletizing. For more information, please visit our newsletter subscription page.