We all have an obligation to think about sustainability. This is important within the manufacturing industry, as well as any other industry. In this article we will talk about the sustainable advantages when automating production. Specifically, we will be using palletizing with collaborative robots (cobots) as an example. Then we will look at how software and simulations can help you get a sustainable solution.

Looking at the global mega trends, climate crisis is impacting businesses. Especially in the wealthy global north, the climate crisis effects investments and how businesses operate. It helps tuning the processes and projects towards more sustainable practices, which has resulted in more investments in technology less harmful to our environment.

Sustainable advantages in cobots

1. Local manufacturing

Keeping manufacturing at a local level, is definitely a step in the right direction.

A sustainable company should try to shorten transportation of production materials. This helps shortening the distance in the supply chain, and therefore reduce transport emissions.

By having the production processes closer to your home, you’ll also gain more control of production and reduce supply transportation costs.

2. Energy consumption

Many of us believe that electric solutions operate sustainably. But it is deeply dependent on how this electricity is made.

Globally, we are still very much dependant on fossil fuels to generate electricity. That’s why we need to do our best to reduce the energy consumption with energy efficient solutions.

Comparing cobots to traditional robots, cobots will generally consume less energy. To ensure low energy consumption, there are few and easy steps operators can do. For instance, running the cobot about 25 percent lower than maximum speed and payload capacity, will reduce the energy consumption and be more energy efficient.

3. Flexible solution

One of the key characteristics of cobots, is its flexibility. This is an important distinction from other robots, as it can easily adapt to various tasks.

Within manufacturing, this is a huge advantage. Especially dealing with a high mix, low volume production and varying costumer needs. This is very typical for SME manufacturing companies.

By quickly adapting to the demand in an easy manner, you will gain more control of the production, avoid potential overproduction and extra waste. It can also reduce the need for specialized solutions, as a cobot could cover several of you production tasks when needed.

4. More quality – Less waste

We have to be honest here. As humans, we do mistakes and we all have good and bad days.

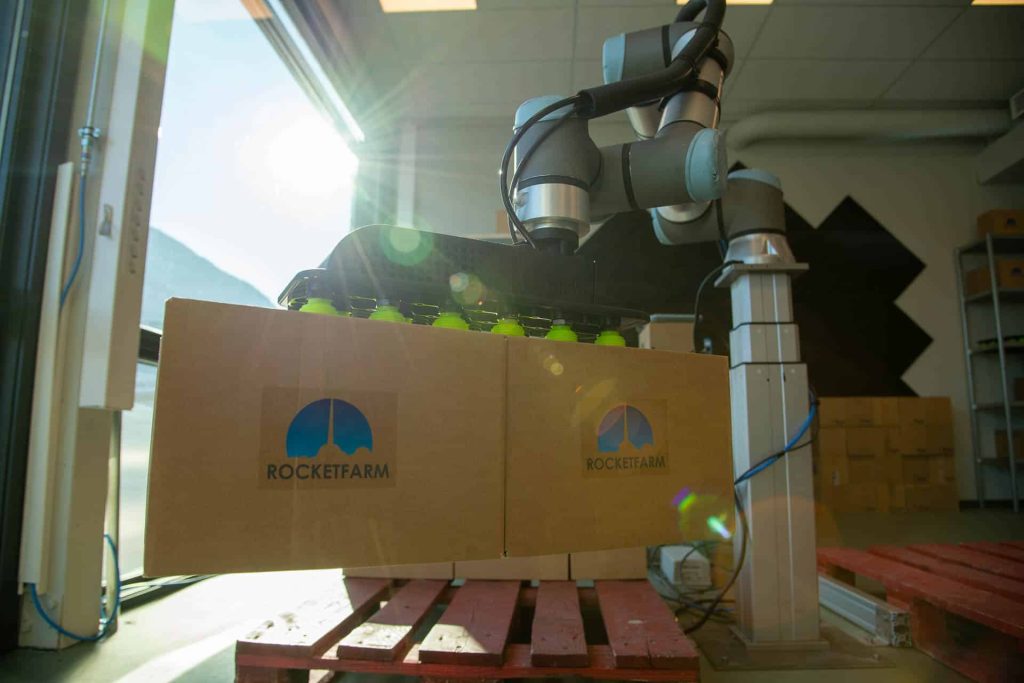

These mistakes can result in spending extra time, money and resources to resolve issues that could otherwise have been avoided. This is not the case with cobots. These systems do what they are designed to do, with perfect repetitive movements.

The point is – the solution we are talking about is simply way better suited for many of the manufacturing tasks. They are contributing to decreasing damaged goods and increasing quality of each and every product leaving your facilities.

The flexible cobots makes no mistakes, unless they’re programmed for mistakes. One of our cobots have been working around the clock for two years, with no exceptions.

Knut Thomassen

Head of Production at Maskinpakking AS

Learn how the increased quality and reliability helped a co-packinging company succeed

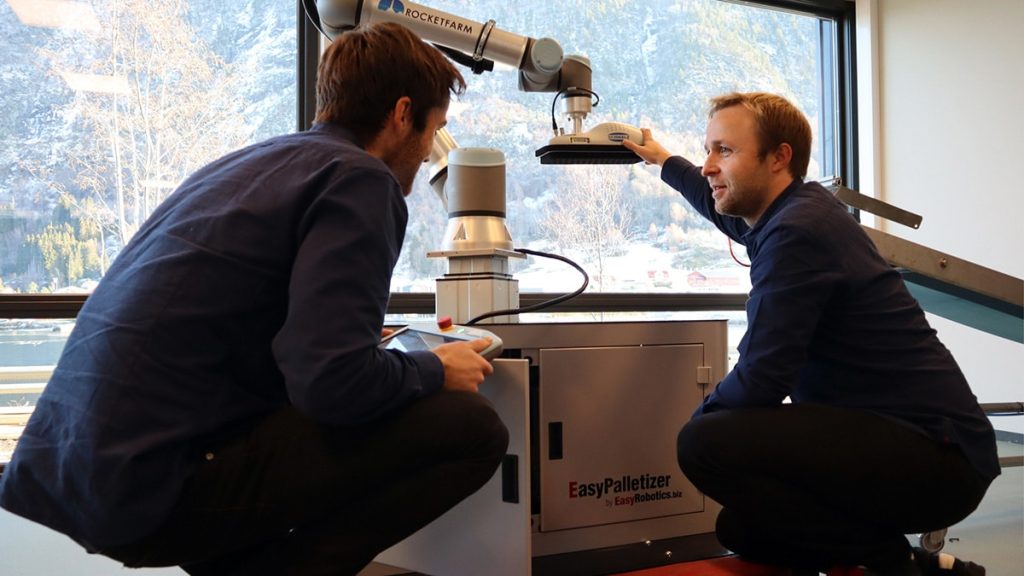

Sustainability in cobot palletizing

At first glance, you might not immediately think of palletizing solutions as having something to do with sustainability. But there are actually several areas where Pally can help you build the most sustainable palletizing solutions.

An important aspect of palletizing solutions using Pally software, is that it is under continuous development. New software updates meant to increase performance, can in itself reduce the overall need for buying new hardware. At the same time, new hardware components together with new software updates can reduce the need for additional cobot installations.

The goal should always be to be able to utilize every solution to its fullest, so we can minimize resource and energy consumption. We do this by continuously strive for making the best possible software applications, with the sustainable software engineering principles in mind. This is a well known model from computer software, but almost completely unknown in the manufacturing world.

None of us would go back to using old operating systems, accounting systems or email clients. It would simply be outdated and slow. We rather stick to new and updated versions, as they progress to be more efficient over time.

When the hardware we have is acting slow, we have to look into the software we’re using. Because we should always make sure we are utilizing the hardware, with the best possible code or program.

Carbon efficiency

By investing in hardware components and cobots, there have already been significant carbon emission from its production. This is known as embedded carbon.

In order act as sustainable companies, we must make sure that we are using the hardware for the longest amount of time. This is about some of the principles in sustainable software engineering – that we don’t waste carbon. Therefore we build applications that are carbon efficient.

Among the many benefits of using Pally software, is the ability to easily manage operational speed though its in-build features like the multipick function. This reduces the wear and tear, and increases the longevity of the cobot.

Roger Almaas

Customer Service Manager at Rocketfarm

Energy efficiency

As the global production of electricity mainly comes from burning fossil fuels, we need to build energy efficient applications. And the best way to look, is through the software. Because the software consumes energy (electricity over time) in all of its task executions.

By using the Pally software, every movement of a complete palletizing solution is fundamentally decided by Pally. That is why we are continuously looking for improvements in the in-build algorithms which will take affect through new software updates. Among other things, this will make sure that the system won’t use more energy than needed.

But these improvements are a double edged sword, as it also benefits the end user directly.

An example is the orientation of the gripper that picks up cases, making sure that it doesn’t make extra unnecessary rotations. This doesn’t only reduce energy consumption, but can also reduce the time to palletize a full pallet. In addition, this helps reduce the cobots wear and tear, making it more hardware efficient.

Hardware efficiency

To achieve carbon efficiency, the software application need to be hardware efficient. Here we focus on two separate areas. This includes the moving parts and those parts that do not move within the cobot palletizing solution.

To make these areas more hardware efficient, we write more efficient code and look for ways to reduce extra movements.

With the Pally software today, there have been many updates to increase performance while lowering the amount of movements. This helps prolonging the lifetime expectancy of any hardware used. Because the longer we can use a cobot and the hardware – the more we make good use of the carbon it took to make it in the first place.

Again, this is also a double edged sword as it naturally benefits the end user. An example could be seen in the software’s ability to utilize hardware, to pick up and place multiple cases in a single cycle. This makes the solution do more with less.

Having an efficient code that provide more performance with less energy, also provide the end user with a long lasting quality solution.

Simulate your way to efficient solutions

Making sure you can find the best palletizing solution is our top priority.

Through our cobot palletizing search engine tool, you can design your own pallet based on your product specifications. By finishing the steps in the Fast Track to Cobot Palletizing, you will get a Digital Twin Simulation and a detailed project analysis within 1 hour.

This way you can see the exact solution operating in real time and get a upfront verification that your palletizing project will work in real life. Additionally, the search engine will suggest possible solution providers based on your region.

Previous methods required a dedicated workforce to film a complete solution, built in a lab, to deliver and provide reassurances that it would work. This meant a lot of unnecessary relocating of hardware, extra costs and time consuming steps. Consequently, this method meant more emissions due to transportation.

Today however, this process has changed completely with our online cobot palletizing search engine.

Automated palletizing – a sustainable choice

With this article we hope that you will have gained some interesting takeaways about sustainability in cobots, and also on how Pally as a software can help you build the most sustainable palletizing solutions.

In essence, the technology has untapped potential and improvements regarding the software features. Hardware upgrades are also continuously being introduced.

Here are the key beneficial aspects using cobots and the Pally software:

1. Benefits using cobots in manufacturing

- It helps keep production local

- Cobots generally consume less energy than industrial robots

- Cobots are flexible, reducing the need for additional solutions

- Contributes to quality and less waste production

2. Benefits using pally palletizing solutions

- Can prolong the lifespan of the hardware, making better use of the embedded carbon

- Hardware will consume less energy

- Hardware will move more efficient

- Get performance boosts through software updates

Making the most out of every palletizing solution is paramount. That is why simulations of the physical robots is such an important tool to verify that these solutions got your back when you need them to.

This makes the investment a trustworthy choice, and a solution that most certainly fits into your specific project. Now and in the future.

Sign up for our newsletter and get a FREE ebook

By signing up for our monthly newsletter, you’ll get case stories, product launches, and tips to automate your production line!

Additionally, you will instantly receive an ebook about implementing palletizing. For more information, please visit our newsletter subscription page.