Many businesses are looking for new ways to turbocharge their manufacturing processes.

The reasons for this are multiple.

Some recognize inevitable future growth in production, while others struggle with older processes that do not support today’s demand. As an end of line production solution, automated palletizing is packed with benefits that affect manufacturing businesses in several ways.

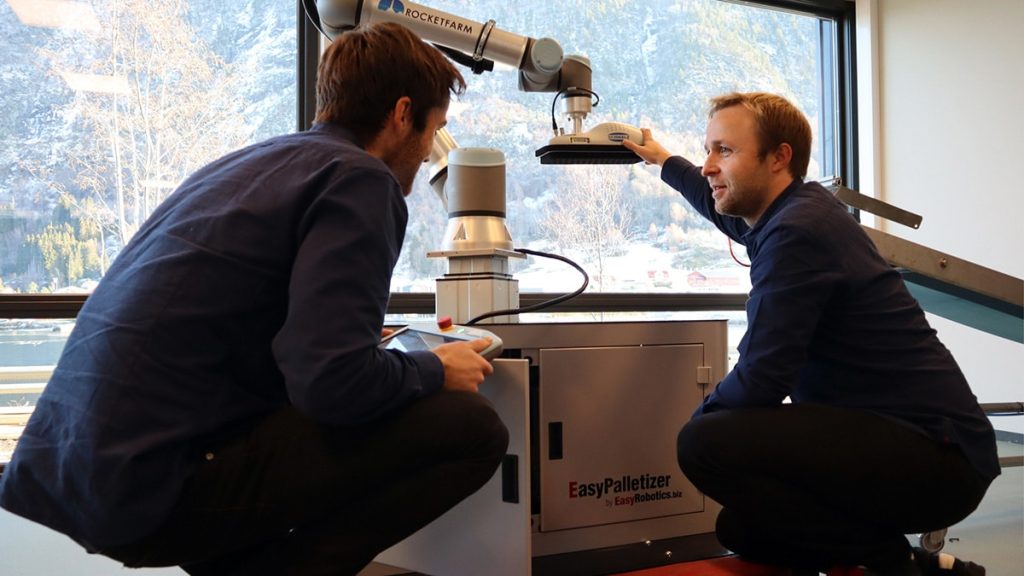

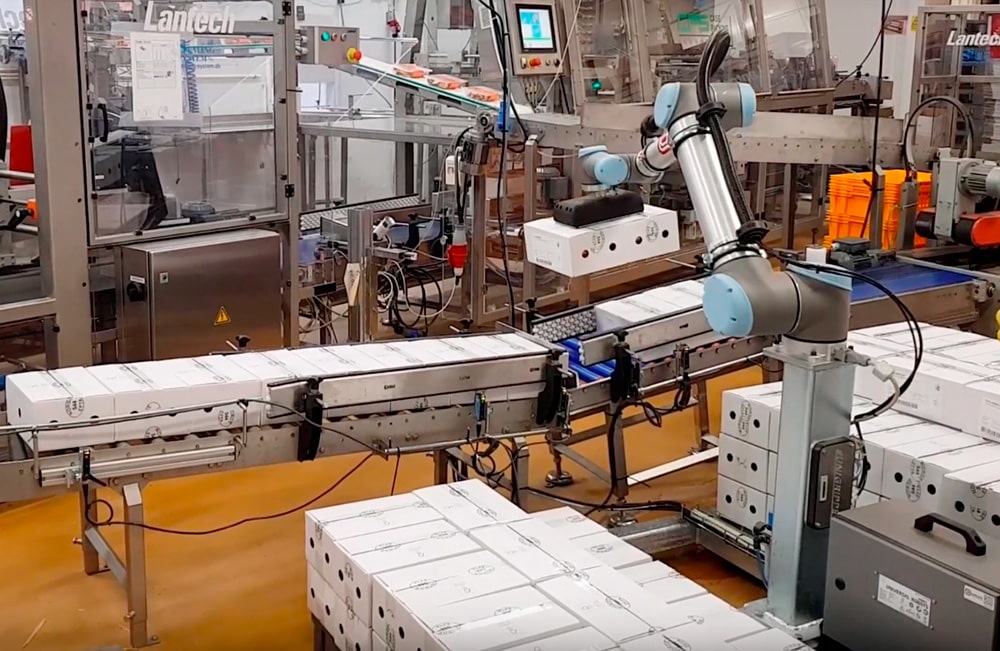

Within automated palletizing, there are two main categories of palletizing systems. The first category is industrial palletizing solutions, which is designed to handle high volume production with a low mix of products. The second category is cobot-powered palletizing solutions, perfectly suitable for medium to small scale production of mixed products. These solutions have individual benefits, but at the same time they also share key advantages for optimizing manufacturing processes.

Learn more about robot vs cobot-powered palletizing solutions here.

In the following paragraphs, we will provide you with insights about the most important benefits you can expect from automated palletizing.

Unleashing human capabilities

The most valuable resources within any organization are the employees, their skills, knowledge, and the ability to cooperate and solve complex problems. Making sure that the employees are working on important tasks, unleashing their potential, should therefore be a priority. This allows businesses to make more use of their existing and valuable resources to drive the organization forward. Additionally, this will also have a positive effect on the work environment.

Improvement in the work environment

Manually stacking endless cases of products not suitable work for the human body. This is a huge issue that is associated with diverse and serious health problems. Automated palletizing solutions will therefore help in creating safer working conditions, reduce potential long term injuries and additional costs that may impose.

Ultimately, this can contribute to increased happiness among employees, as they can focus on other, less tedious and strenuous tasks.

Increased cost effectiveness

You can expect long term and good results by investing in automated palletizing solutions. These machines do not take a day off, and handle products as they come out the end of the production line, finished, ready for palletizing and delivery.

This means that there will be less down time, as it helps against future bottlenecks and also increasing throughput capabilities in the production. This benefit applies to most manufacturing businesses, as you can choose palletizing systems that fit your volume of manufacturing.

The cobot palletizing solutions are the robots we have with highest operating time and lowest running costs

Inghild Lysne Sanden

Factory Manager Nortura Sogndal

Improvement in product quality

Automated palletizing solutions are designed to be efficient, precise and consistent. This way, you can expect the desired end of the line result, stacked perfectly on a pallet every time. In contrast, manually stacking cases can involve accesional blunders, as no human works like a robot (or cobot). These palletizing solutions will help avoid potential damaged products leaving your facilities and further decrease returns and damaged product claims.

Return on investment

Instead of struggling to find a workforce dedicated to stacking cases, investing in automated palletizing solutions can be a beneficial investment. Cobot palletizing solutions have an estimated return on investment between just 6 – 12 months, while industrial palletizing solutions are more of a long term investment. Depending on the ambitions of the business and other variables, long term use of any palletizing product will eventually be a cost-saving machine.

Learn more about key points to consider when calculating return on investment for a palletizing solution.

Prepare for the future

As a way to armor yourself up against a competitive market and the future, automated palletizing is particularly useful. Through this article we have mentioned several important benefits to expect from adopting automated palletizing.

Learn how a norwegian co-packaging company is utilizing cobot palletizing to compete with companies from countries with lower wages.

Firstly, it’s about allowing employees to make use of their skills and knowledge, working on important tasks, which will positively affect and strengthen the safety of the work environment. Secondly, we have mentioned several economical benefits, from increased cost effectiveness, product quality and positive return on investment.

Combining these benefits, we can understand how these innovative technologies can help maintain and strengthen the competitive edge within most manufacturing businesses.

Learn more about the pros and cons in collaborative robots here

Do your products weigh below 15 kg and have a production rate less than 30 cases per minute? We can offer you an easy transition to automated palletizing with cobots. Simply get a FREE digital twin simulation and a project report of your palletizing project below. This will serve as a upfront verification of your palletizing project. As we usually say; if it can be done in our simulation, it can be done in real life!

Sign up for our newsletter and get a FREE ebook

By signing up for our monthly newsletter, you’ll get case stories, product launches, and tips to automate your production line!

Additionally, you will instantly receive an ebook about implementing palletizing. For more information, please visit our newsletter subscription page.