This article will cover the topic of palletizing with cobots, also called cobot palletizing. It will try to cover all the different aspects of palletizing with cobots and what you need to be aware of if you are considering af cobot palletizing solution for your production.

But first the basics.

What is Palletizing?

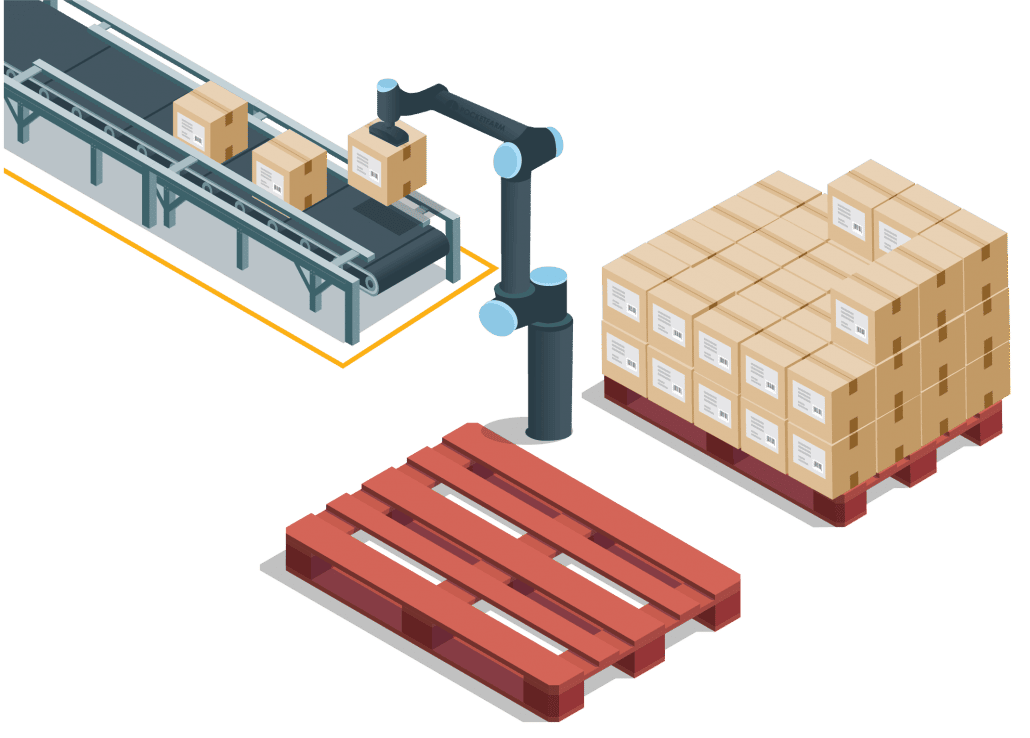

The process of palletizing involves placing products on pallets for shipment or storage in a supply chain. It can be achieved in a variety of ways, but ideally the maximum amount of products is placed on the pallet. In addition to maximizing the amount of products on the pallet, it should be stacked in a way that is stable enough to withstand any stress it might be exposed to when shipping.

Traditionally, this is a labor-intensive task usually performed by hand. With the progress of the fourth industrial revolution, more or less automated systems are gradually taking over and this is where cobots is one of the options available.

What are Cobots (collaborative robots)?

Cobots are robots that are designed to work alongside humans and collaborate with them while solving a task; they provide a cost-effective, safe, and versatile way to do everything from quality inspections to palletizing while collaborating with humans. In addition to all of these advantages, collaborative robots are simplifying the automation process more than ever before. Making advanced automation available for even for small and medium sized businesses.

In short, they are robots that do not need to be caged to work alongside humans; they are collaborative.

What makes up a palletizing solution

By using sophisticated software and capable hardware, palletizing is no longer a task for manual labor. Palletizing software is the brains of the operation, you might think it doesn’t take much to place boxes on a pallet, but the software is designed to run on millimeter precision and lets you customize your own patterns without any downtime.

To start your journey towards automating your production with a palletizing cobot, you can check and verify your project here.

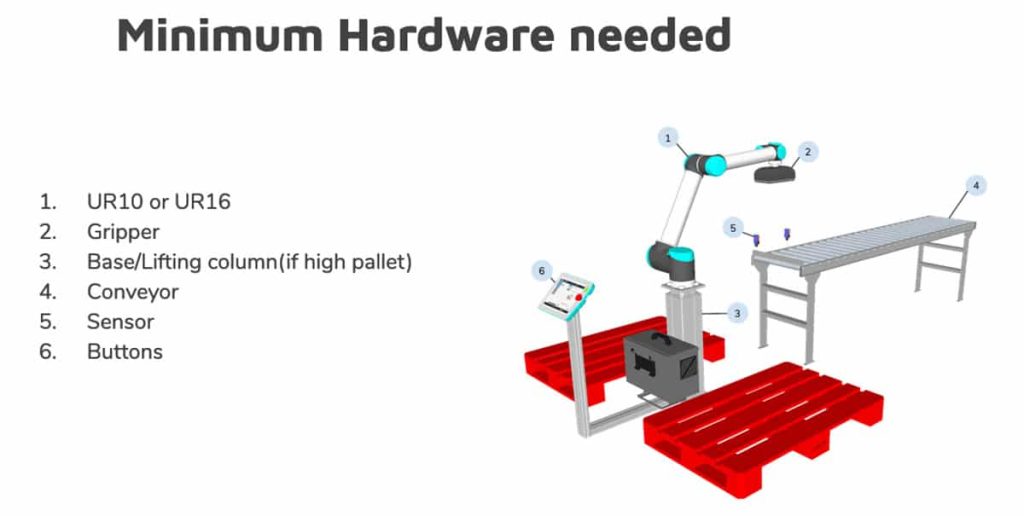

Hardware

This is the moving parts executing the tasks, the minimum hardware needed is a cobot, Gripper, Base/lifting column (depending on height), conveyor, sensor and buttons.

Universal Robots also recently announced their new UR20 cobot, with a max payload of up to 20 kg. It may not be certain, but they expect to be shipping in Q2 2023 and will begin to sell the robot in Q4 2022.

Click here to learn more about UR20 cobot palletizing

Pally Software

Pally is a palletizing URcap designed to be seamless, flexible, and quick to install.

With our software, your palletizing operations will be simple and easy to use. It is able to handle changes in production without requiring any downtime, allowing you to fully utilize the cobot’s potential for present and future production.

Pattern

This is how your products are stacked on the pallet to suit your specifications. Quite simply, build a pallet pattern in MyRobot.cloud, upload it to the URCap, and start palletizing your custom pattern.

By watching the video below, you will see a tutorial that guides you through setting up a new pattern in MyRobot.cloud.

What can you expect from cobot palletizing?

Precision, reliability, and quick and easy installation.

A cobot is expected to perform the task with no mistakes and with a work ethic that only machines can possess. You will get a safe and reliable worker equipped with functions to ensure the safety of others, this includes a stop function if the cobot collides with something or someone, adjustable speeds and emergency stop button. A cobot also adds resilience to your production as it is always there to do the job. As perfectly as programmed. Every time.

Faster and easier deployment

When choosing a palletizing solution, you can expect a quick process from setting up hardware to production. An example of this is Taylormade’s recent installation by A.I Automation:

“With the partnership we have with Rocketfarm and Pally, we were able to have a unit fabricated, validated, and installed in 3 weeks, far less time than a traditional automation company”

The cobot palletizing solution as TaylorMade has, since installation in mid-October 2021, has been running 24/7 without any issues

Cases like this reflect the many advantages of cobot solutions, if you want to discover more advantages and possibilities the next section is for you.

Palletizing with Universal Robots

To be fair, most collaborative robots can do palletizing tasks. But some brands are highly suitable for this kind of job. One of these brands comes from Universal Robots, the leading cobot manufacturer.

Click here to read the article “Palletizing with Universal Robots: All you need to know”.

Pros and cons of cobot palletizing

Advantages

There are numerous advantages to using a cobot, let’s start with the obvious: Cobots don’t need breaks, they don’t need holidays, and they don’t call in sick. By implementing a cobot, you get a worker who is always accurate and on time.

There are lots of good examples where a cobot has effectively increased production and liberated human resources from repetitive and weight-bearing physical labor (like palletizing) to more meaningful tasks. In addition to being an exceptional resource, the expected return on investment time is really short, in most cases less than a year.

Why not just use an industrial robot?

For traditional industrial robotic systems, heavy fence guards and peripheral safety equipment are required, this can lead to a reduction in flexibility and will severely increase costs and space requirements. Cobots, on the other hand, are designed to coexist with human beings and share the same workspace.

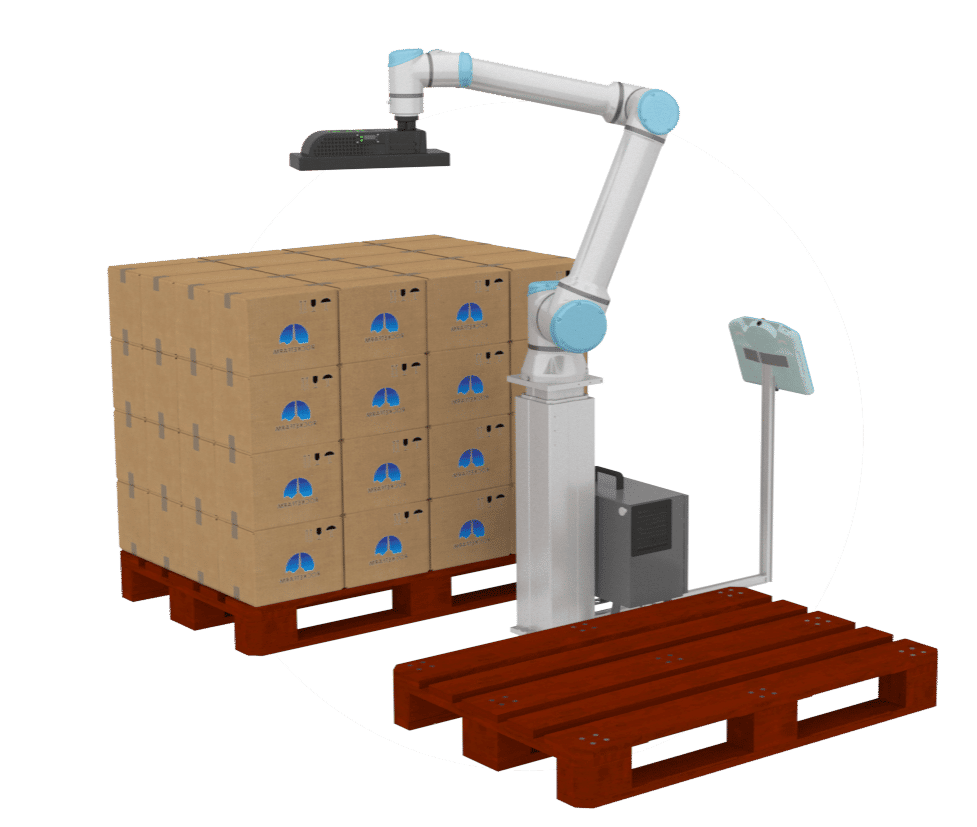

A cobot palletizing solution can have a footprint as small as 0,16 sqm (+ pallets)

Click here to learn more about cobot vs robot palletizers here

Disadvantages

Compared to an industrial robot, payload and speed are significantly lower. For the cobot to be able to work without physical safety installations, it has to move slower, and the design of the cobot also limits the payload. A cobot palletizing solution is, therefore, not an obvious choice for high volume low, mixed production lines.

Work speed can be additionally impacted by its safety measures. A cobot should slow down or stop if it detects a person in its working environment.

Human–robot collaboration is a new frontier for robotics, and the human–robot synergy will constitute a relevant factor in industry for improving production lines in terms of performances and flexibility. This will only be achieved with systems that are fundamentally safe for human operators, intuitive to use, and easy to set up

Matheson, Minto, Zampieri, Faccio, & Rosati, 2019

Low risk – high reward

Cobots represent a low barrier for automation where the initial investment (and risk) is limited, but the potential gain is substantial and ROI short. Especially in markets with labor shortages, the benefits of a cobot (and automation in general) can hardly be underestimated.

Nothing beats an employee (the cobot) who shows up every day and does their job (simple but boring and dangerous) to perfection every time.

A bright future

Industry experts are predicting a great future for cobots and industry 4.0. The possibilities are many and diverse. By different programming and new tasks the cobots are expanding their area of expertise, palletizing cobots are getting more and more capable in terms of lift capacity, effectivity and reach. This means that you could lift heavier products and palletize higher, longer, and wider.

Because of the short ROI, a cobot turns profitable really fast and allows you to deploy human resources on other more valuable tasks than stacking cases.

When all things are considered, the key takeaway from this article is that the limitations and disadvantages of a cobot palletizing solution are far less than the possibilities and advantages. And it doesn’t have to be difficult to start.

Let Rocketfarm provide you with an upfront verification of your palletizing project by using digital twin simulations. This way, you’ll get trustworthy proof of whether your project can be solved by a cobot palletizing solution.

Sign up for our newsletter and get a FREE ebook

By signing up for our monthly newsletter, you’ll get case stories, product launches, and tips to automate your production line!

Additionally, you will instantly receive an ebook about implementing palletizing. For more information, please visit our newsletter subscription page.