Chances are, the last time you shopped at a supermarket, you passed by a display pallet – likely stacked by human hands. But that’s quickly changing. Manual palletizing of display pallets, once the standard, is becoming a thing of the past –

and Pally is an important participant in making automation a reality.

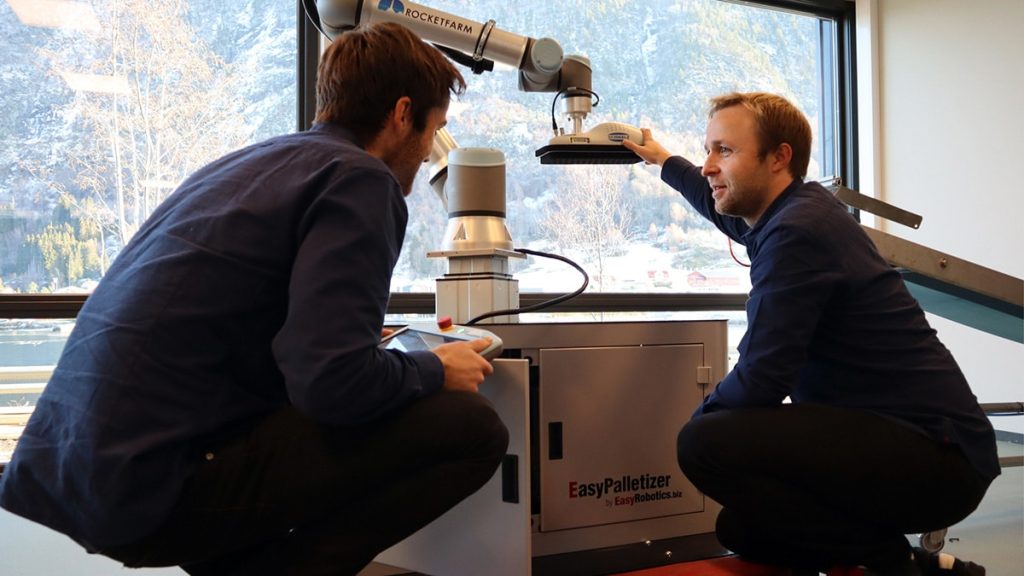

After Automation. Photo: Kameleon Gruppen

For a long time, display pallets have been a challenge for automation. Their unique sizes and the complexity of handling multiple products have made it difficult to apply traditional palletizing solutions.

However, technological advancements are transforming what was once a tough task into an automated process, increasing speed, precision, and efficiency.

“Traditionally, display pallets were manually assembled because most production lines are built to handle only standard-sized EU pallets,” says Lasse Erlandsen, Sales and Robot Product Manager at Kameleon Gruppen.

Another complication is that display pallets often contain a mix of two to five different products. Overcoming this requires collaboration between marketing teams, cardboard suppliers, customers, and software developers.

“There are many challenges with display pallets, but we intend to solve them,” says Erlandsen.

The Shift to Automation

Their work automating canned corn display pallets showcases the power of automation in what used to be a labor-heavy process.

Previously, these pallets were built in warehouses. This is a time-consuming, physically demanding task involving excessive bending and lifting. Automating this process has resulted in cleaner, more visually appealing pallets, reducing cardboard waste and minimizing the need for extra packaging materials.

See the process in this video:

Software as the Key to Success

As the demand for display pallets continues to rise and businesses increasingly recognize their impact on sales, Kameleon Gruppen is now focusing on tackling the next challenge: automating multi-product display pallets.

Pally software is essential in making this possible. By streamlining the palletizing process, Pally turns the complexity of handling display pallets into an accessible, efficient task.

“With Pally, we can create custom pallet patterns and generate pallet sizes tailored to specific needs,” says Erlandsen. “The software also allows us to simulate the palletizing process beforehand, providing valuable insights into expected performance and speeds.”

Easily Meet Your Customers’ Demands with Pally

One of Pally’s biggest advantages is its flexibility. As requirements evolve, you will be able to quickly generate new pallet patterns, offering limitless flexibility to meet customer demands.

Whether you’re dealing with ever-changing products or managing different pallet sizes, Pally ensures that your display palletizing process is seamless and efficient.

Are you ready to discover how display pallet automation can benefit your business? Learn more about Pally, our user-friendly palletizing software, and how it’s revolutionizing display pallets on our website.

We’re here to help! Don’t hesitate to reach out with any questions about automating your palletizing processes.

Torgeir

Account Manager, Rocketfarm AS