Rocketfarm + Piab = Freyja

1.

Palletizing Software,

by Rocketfarm

The Rocketfam package consists of its Pally URCap, the web-based Pallet Builder and Digital Twin Simulations software.

2.

Cobot Palletizing Tool,

by Piab

Piab’s multi-zone gripper with a foam or suction cup based surfaced also comes with URCaps and is equipped with the latest COAX® vacuum ejector and piSMART® valve unit.

3.

Completely integrated tool, Freyja

The perfectly adapted gripper / software solution ensures, you get the maximum out of each, optimizing your robot investment and reaching ROI in the shortest possible time.

Two industry experts. One joint solution.

Deep knowledge of palletizing has come together to bring market leading innovations into your next UR palletizing project.

Rocketfarm is a Norwegian tech-company with deep roots in industrial automation. We were founded by engineers and our mission is to create better and safer places for people to work.

A swedish company, Piab specialises in automated process components and solutions to enable gripping, lifting and moving applications for our customers in all industries.

What can a Freyja Palletizing solution handle?

If your products and CPM requirements are within the light blue or dark blue area, then a Freyja Palletizing Solution can handle your palletizing needs.

PALLY Software, by Rocketfarm

What Pally will do for you is to make the robot incredibly easy to operate and it is compatible with most hardware on the market. This means our partners can get the solution that fits your current (and future) needs. And if necessary down-the-road they can help you with hardware upgrades. Pally makes the life easier for your operators and ensures that you get the best possible palletizing solution.

Let us help you with an upfront verification of your specific palletizing project.

3 Reasons to choose a Freyja Palletizing Solution

Flexible to changes in production.

Switch between patterns without downtime and without reprogramming the software. Easily add new products in the future.

Increased safety

With the most advanced multipick possibilities on the market, a Pally solution will be able to lower robot moving speed and thereby increase safety, while still reaching your requirements. This also enhances the longevity of the robot.

Short ROI in less than 1 year

By being able to choose the best suited hardware and the ease-of-use your ROI will be very short and less than 1 year. Even shorter if you run several shifts.

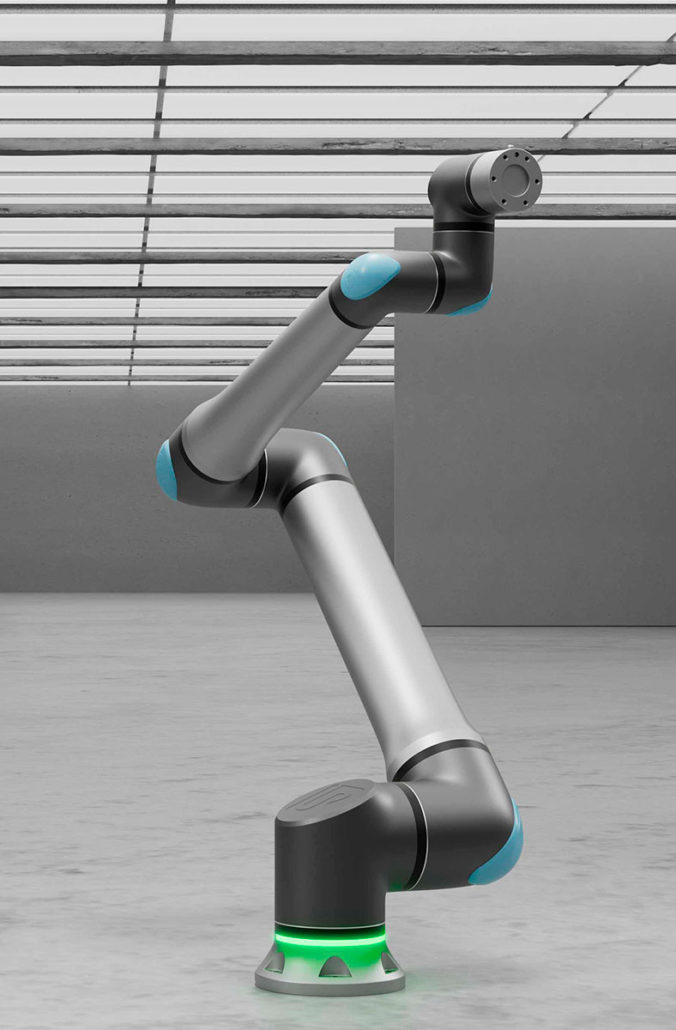

Freyja – compatible with UR20

Freyja is a UR Cobot Palletizing solution and works with any cobot from Universal Robots. This also applies to the coming UR20.

UR20

With a 20 kg payload capacity and a 1750 mm reach, the new UR20 from Universal Robots is a palletizing robot by design. It is still very collaborative, with a footprint less than a dinner plate and weighs only 64 kg.

Solution for many projects

Freyja will be compatible with UR20 when the cobot is released. The combination of Freyja’s ability to maximize the effort of each pick and UR20s’ high reach and capacity makes it a solution with tremendous potential.

Upfront Verification

With our Digital Twin Simulation, you will be able to have an upfront verification of the palletizing solution with Freyja and a UR cobot. In this way, you will be able to find the palletizing solution that solves your exact need.

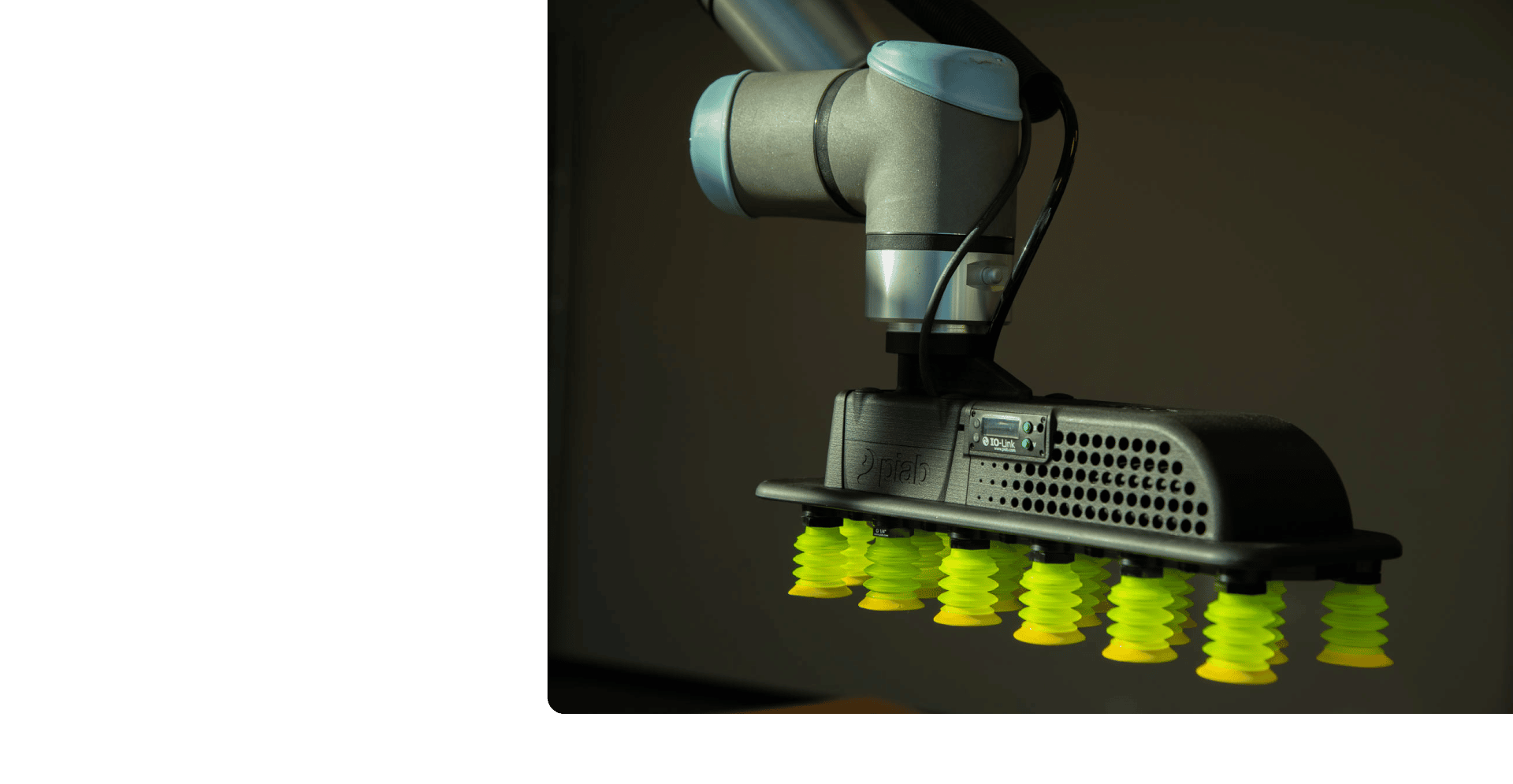

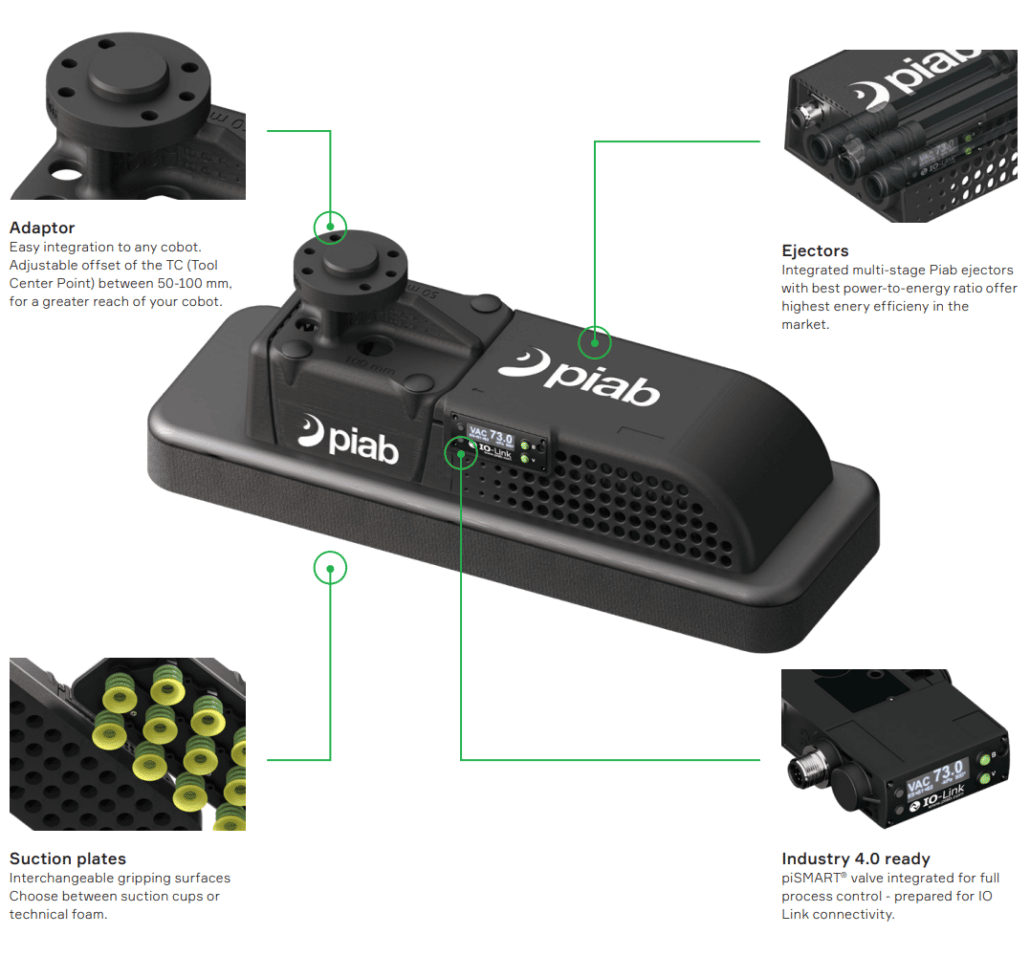

Cobot palletizing tool – CPT, by PIAB

The CPT (cobot palletizing tool) is a smart and compact cobot gripper, allowing you to get more products out at the same time and at lower cost.

Its multi-zone gripper surface picks several boxes even of different shapes in the same cycle. While its light-weight body allows a higher throughput per pick. Including the piSMART® valve unit further ensures maximum necessary speed of operations and enables predictive maintenance for highest possible uptimes.

- Higher pallet output per day

- Up to 80% less tool cost, needing only 1 EOAT

- COAX® technology for high energy efficiency

CPT – Component details

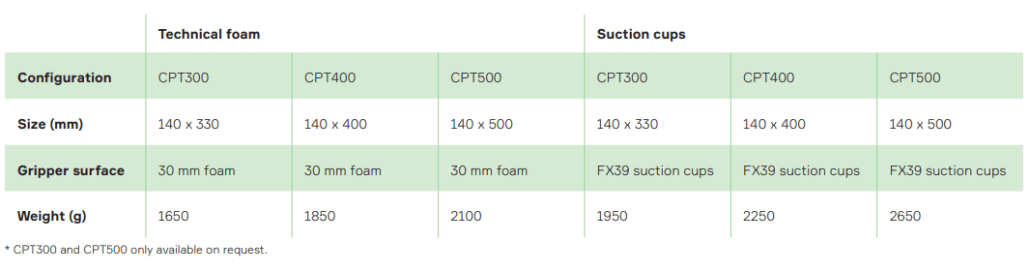

Configuration variants – Technical specifics of variants

Combined solution- Freyja

Freyja is the most powerful yet cost-effective UR cobot palletizing solution

–

assisting in the process design, simulation, and operation in a safe and efficient way.

From A to Z, from layer planning to pallet delivery – Freyja helps SME’s in FMCG and other industries to optimize palletizing process.

Combining the best of two worlds resulted in an intuitive plug & play solution of modular design with standard components facilitating a quick exchange of readily available components if needed. Enabling multi-picking through its hard- and software features, the system allows to reduce speed, while allowing high productivity, which increases safety and robot life-time.

Flexible to future changes in production

Fast operations due to multi-picks in one cycle

Longer robot life-time due to less wear

Get upfront verification

By using advanced algorithms and visualization tools we are able to calculate, predict and visualize how a given solution (different hardware, software settings etc.) will perform and if it will meet your production requirements.

It has never been easier to get an upfront verification (proof of concept) of your palletizing projects. Request a digital twin simulation from Rocketfarm (from basic box dimensions and production speed) and receive a complete project report and a digital twin simulation of the solhe Freyja solution palletizing in real time.